Hasung Silver Block Casting Production Line: Efficient and Accurate Silver Block Manufacturing Solution

The Hasung silver block casting production line adopts advanced automation equipment to ensure efficient and high-precision production from silver raw materials to finished silver blocks. The entire production line includes four core equipment: granulator, vacuum ingot casting machine, embossing machine, and serial number marking machine. Each link has been optimized to ensure the quality, accuracy, and traceability of silver blocks.

1. Granulator: precise preparation of silver particles

Function: Process silver raw materials into uniformly sized particles to ensure uniformity in subsequent casting.

Advantages:

① Efficient and energy-saving

By adopting optimized screw design and electromagnetic heating technology, it saves 15% to 30% energy compared to traditional granulators, while maintaining high output and reducing production costs.

② Uniform and stable particles

Equipped with precision molds and multi blade cutting systems, ensuring consistent particle size (with an error of ± 0.1mm), suitable for industries that require high precision, such as pharmaceuticals and food.

③ Intelligent automation control

PLC+touch screen operation, real-time monitoring of temperature, speed and other parameters, automatic fault alarm, reducing manual intervention, and improving production efficiency.

④ Durable and easy to maintain

The key components (screws, barrels) are treated with wear-resistant alloys or coatings for longer service life. The modular design makes maintenance more convenient and reduces downtime.

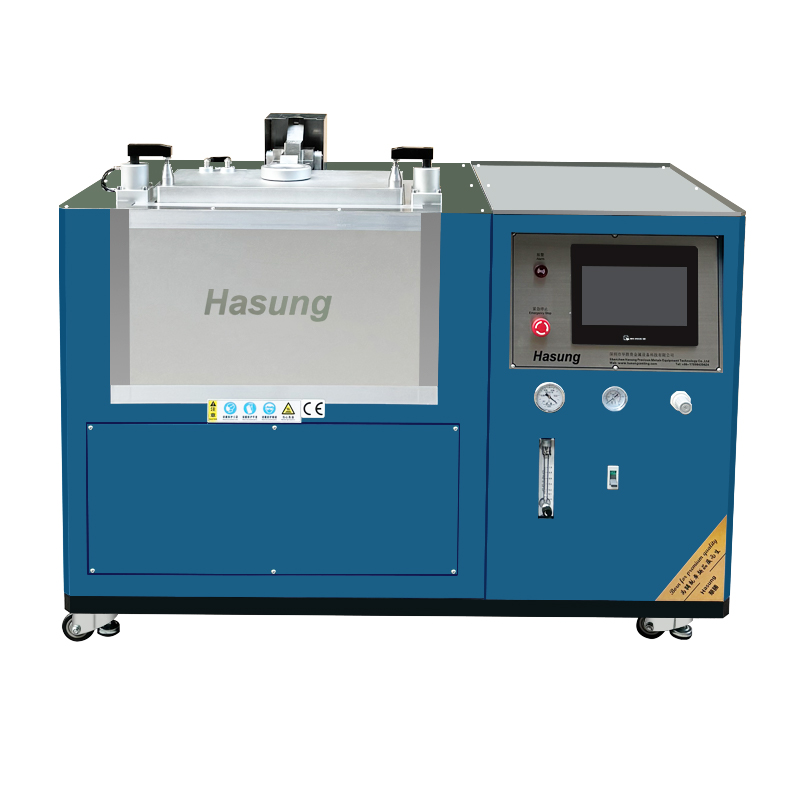

2. Vacuum Ingot Casting Machine: Creating High Purity Silver Blocks

Function: Melt and cast silver particles into smooth, impurity free silver blocks, ensuring high density and surface smoothness.

Advantages:

① High purity ingot

Adopting vacuum melting technology, effectively reducing oxidation and impurity mixing, suitable for casting high-purity metals such as titanium, zirconium, and special alloys, ensuring stable material properties.

② Uniform crystalline structure

The precise temperature control system, combined with directional solidification technology, refines the internal grain size and uniform structure of the ingot, reduces segregation, and improves subsequent processing performance.

③ Efficient and energy-saving

Optimize the design of heating and cooling systems, reducing energy consumption by 20% to 30% compared to traditional ingot casting equipment, while maintaining high production efficiency (such as a single furnace processing capacity of up to 1-5 tons).

④ Automated intelligent control

PLC+human-machine interface (HMI) monitors parameters such as vacuum degree, temperature, pressure in real-time, supports data recording and process tracing, reduces human errors, and makes operation more convenient.

3. Embossing machine: high-precision pattern imprinting

Function: Imprint customized patterns such as brand logo, weight, purity, etc. on the surface of silver blocks.

Advantages:

① High precision embossing

The equipment has precise pressure control and stable operating structure. When imprinting silver blocks, the details such as patterns and markings can be clearly presented with high dimensional accuracy, ensuring the consistency of silver block imprinting. For example, when making commemorative coin silver blocks, fine patterns can also be accurately restored.

② Efficient homework

It can quickly complete the silver block stamping process, shorten the processing time of individual silver blocks compared to traditional methods, improve batch production efficiency, help enterprises deliver orders in a short period of time, and meet the market's demand for silver products.

③ Stable quality

The pressure during the embossing process is uniform and the operation is stable. The appearance quality of the silver block after embossing is good, and it is not prone to deformation, damage and other problems, which improves the yield of silver products and reduces the cost loss caused by defective products.

④ Versatile adaptation

Capable of adapting to different specifications and shapes of silver block embossing, whether it is small silver bars, complex shaped silver jewelry components, or conventional silver blocks, the parameters can be adjusted for embossing, flexibly meeting diverse production needs.

4. Serial number marking machine: Ensure traceability

Function: Laser engrave unique serial numbers, production dates, batch numbers, and other information on silver blocks.

Advantages:

① Accurate and clear

It can accurately restore serial numbers, with neat strokes and even depth of characters and numbers. Even in long-term use and complex environments, the markings are not easily blurred, ensuring the accuracy of serial number recognition and facilitating product traceability management.

② Easy to operate

The layout of the device buttons is reasonable, combined with a simple control system. Personnel can easily get started after simple training, and can quickly set the marking content and parameters, reducing the operating threshold and labor costs.

③ Efficient and stable

The marking process is coherent, able to quickly complete serial number marking, and runs stably with few long-term work failures, improving the efficiency of batch product marking and helping to promote production rhythm.

④ Widely adaptable

It can adapt to various materials and shapes of workpieces for marking, and can stably mark flat and small curved workpieces made of metal and some non-metal materials, meeting the marking needs of different product serial numbers.

Comprehensive advantages of production line

✅ Fully automated process: reduces manual intervention and lowers the risk of errors.

✅ High precision control: strict quality inspection at every stage to ensure that the purity of silver blocks is ≥ 99.99%.

✅ Flexible and scalable: adjustable parameters to adapt to different specifications (1kg/5oz/100g, etc.) of silver block production.

✅ Complies with international standards: meets industry certification requirements such as ISO.

conclusion

The Hasung silver block casting production line has become a benchmark solution in the precious metal processing industry, thanks to the efficient granulation of the granulator, precision forming of the vacuum ingot casting machine, clear identification of the embossing machine, and full traceability of the serial number marking machine. Whether investing in silver bars, industrial silver materials, or high-end collectibles, this production line can provide stable and high-quality silver block products.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115