Hasung ndi katswiri wopanga makina osungunula zitsulo zamtengo wapatali kuyambira 2014.

Hasung Silver Block Casting Production Line: Njira Yabwino Yopangira Silver Block Manufacturing Solution

Mzere wopangira siliva wa Hasung umatenga zida zodziwikiratu kuti zitsimikizire kuti zikupanga bwino komanso zolondola kwambiri kuchokera kuzinthu zopangira siliva mpaka midadada yomalizidwa yasiliva. Mzere wonse wopanga umaphatikizapo zida zinayi zazikulu: granulator, vacuum ingot kuponyera makina, embossing makina, ndi siriyo nambala cholemba makina. Ulalo uliwonse wakonzedwa kuti zitsimikizire mtundu, kulondola, komanso kutsata kwa midadada yasiliva.

1. Granulator : Kukonzekera kolondola kwa tinthu tasiliva

Ntchito: Sinthani zida za siliva kukhala tinthu tating'ono tofananirako kuti tiwonetsetse kuti ndizofanana pakuponyedwa kotsatira.

Ubwino:

① Kuchita bwino komanso kupulumutsa mphamvu

Pogwiritsa ntchito makina opangira ma screw ndi ukadaulo wotenthetsera wamagetsi, imapulumutsa mphamvu 15% mpaka 30% poyerekeza ndi ma granulator achikhalidwe, ndikusunga zotulutsa zambiri ndikuchepetsa ndalama zopangira.

② Tinthu ting'onoting'ono komanso tokhazikika

Okonzeka ndi nkhungu mwatsatanetsatane ndi Mipikisano tsamba kudula kachitidwe, kuonetsetsa kusasinthasintha tinthu kukula (ndi cholakwika ± 0.1mm), oyenera mafakitale amene amafuna mkulu mwatsatanetsatane, monga mankhwala ndi chakudya.

③ Kuwongolera mwanzeru zochita zokha

PLC + touch screen operation, kuwunika kwenikweni kutentha, liwiro ndi magawo ena, alamu yamagetsi yokhayokha, kuchepetsa kulowererapo pamanja, ndikuwongolera magwiridwe antchito.

④ Zokhalitsa komanso zosavuta kuzisamalira

Zigawo zazikulu (zopangira, migolo) zimathandizidwa ndi ma alloys osamva kapena zokutira kwa moyo wautali wautumiki. Mapangidwe a modular amapangitsa kukonza kukhala kosavuta komanso kumachepetsa nthawi yopumira.

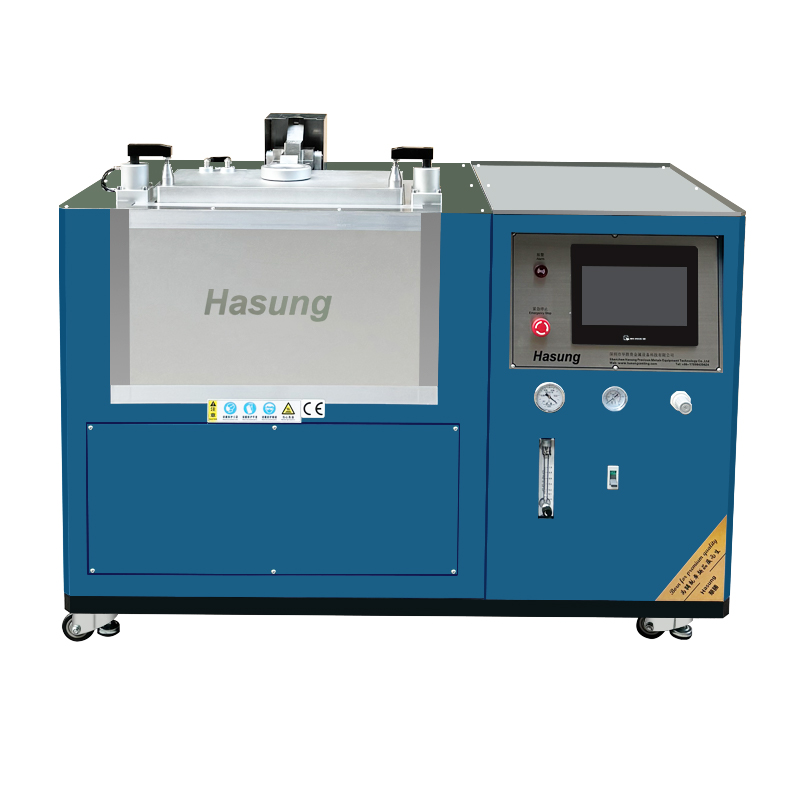

2. Makina Oponya a Ingot a Vacuum : Kupanga midadada Yasiliva Yoyera Kwambiri

Ntchito: Sungunulani ndi kuponyera tinthu tating'ono ta siliva muzitsulo zasiliva zosalala, zosadetsedwa, kuwonetsetsa kuti kachulukidwe kwambiri komanso kusalala kwa pamwamba.

Ubwino:

① Kuyeretsa kwakukulu

Kutengera ukadaulo wosungunula vacuum, kuchepetsa bwino makutidwe ndi okosijeni ndi kusakanikirana konyansa, koyenera kuponyera zitsulo zoyera kwambiri monga titaniyamu, zirconium, ndi ma alloys apadera, kuwonetsetsa kuti zinthu zili bwino.

② Kapangidwe ka kristalo kofanana

Njira yolondola yoyendetsera kutentha, yophatikizidwa ndi ukadaulo wokhazikika wowongolera, imawongolera kukula kwa tirigu wamkati ndi mawonekedwe ofanana a ingot, imachepetsa kugawanika, ndikuwongolera magwiridwe antchito motsatira.

③ Kuchita bwino komanso kupulumutsa mphamvu

Konzani mapangidwe a makina otenthetsera ndi kuziziritsa, kuchepetsa kugwiritsa ntchito mphamvu ndi 20% mpaka 30% poyerekeza ndi zida zachikhalidwe zoponyera ingot, ndikusunga magwiridwe antchito apamwamba (monga ng'anjo imodzi yopangira ng'anjo mpaka matani 1-5).

④ Kuwongolera mwanzeru

PLC + human-machine interface (HMI) imayang'anira magawo monga vacuum degree, kutentha, kuthamanga mu nthawi yeniyeni, imathandizira kujambula kwa data ndikutsata ndondomeko, imachepetsa zolakwika za anthu, ndikupangitsa kuti ntchito ikhale yosavuta.

3. Embossing makina: mkulu-mwatsatanetsatane chitsanzo imprinting

Ntchito: Kusindikiza makonda makonda monga chizindikiro cha mtundu, kulemera, chiyero, etc. pamwamba midadada siliva.

Ubwino:

① Zojambula zolondola kwambiri

Zipangizozi zimakhala ndi mphamvu zoyendetsera bwino komanso zokhazikika zogwirira ntchito. Mukasindikiza midadada ya siliva, tsatanetsatane monga mapatani ndi zolembera zimatha kuwonetsedwa bwino kwambiri, kuwonetsetsa kuti kusindikiza kwa siliva kumagwirizana. Mwachitsanzo, popanga midadada yachitsulo yachikumbutso, zitsanzo zabwino zimatha kubwezeretsedwanso molondola.

② Homuweki yabwino

Itha kumaliza mwachangu ndondomeko yopondaponda siliva, kufupikitsa nthawi yokonza midadada yasiliva payekha poyerekeza ndi njira zachikhalidwe, kukonza magwiridwe antchito a batch, kuthandizira mabizinesi kupereka maoda munthawi yochepa, ndikukwaniritsa zomwe msika ukufunikira pazinthu zasiliva.

③ Khalidwe lokhazikika

Kupsyinjika pa nthawi ya embossing ndi yunifolomu ndipo ntchitoyo imakhala yokhazikika. Maonekedwe amtengo wapatali wa siliva pambuyo pa embossing ndiabwino, ndipo siwongopeka, kuwonongeka ndi zovuta zina, zomwe zimapangitsa kuti zokolola za siliva zizikhala bwino ndikuchepetsa kutayika kwa mtengo komwe kumachitika chifukwa cha zolakwika.

④ Kusintha kosinthika

Wotha kusinthira kumitundu yosiyanasiyana komanso mawonekedwe a siliva block embossing, kaya ndi tizitsulo tating'ono tasiliva, zida zasiliva zowoneka bwino zowoneka bwino, kapena midadada wamba wasiliva, magawowa amatha kusinthidwa kuti azikongoletsa, kukwanitsa kukwaniritsa zosowa zosiyanasiyana zopanga.

4. Makina ojambulira nambala ya seri: Onetsetsani kuti mukutsata

Ntchito: Laser jambulani manambala apadera, masiku opanga, manambala a batch, ndi zina zambiri pama block asiliva.

Ubwino:

① Zolondola komanso zomveka

Ikhoza kubwezeretsanso manambala a seriyo molondola, ndi mikwingwirima yabwino komanso kuya kwa zilembo ndi manambala. Ngakhale pakugwiritsa ntchito kwanthawi yayitali komanso m'malo ovuta, zolembera sizimawonekera mosavuta, kuwonetsetsa kulondola kwa kuzindikira kwa nambala ya serial ndikuwongolera kasamalidwe kazinthu.

② Yosavuta kugwiritsa ntchito

Mapangidwe a mabatani a chipangizo ndi omveka, ophatikizidwa ndi dongosolo losavuta lolamulira. Ogwira ntchito amatha kuyamba mosavuta pambuyo pa maphunziro osavuta, ndipo amatha kuyika zolembera mwachangu ndi magawo, kuchepetsa ndalama zogwirira ntchito komanso ndalama zogwirira ntchito.

③ Yogwira mtima komanso yokhazikika

Kuyika chizindikiro ndikogwirizana, kumatha kumaliza mwachangu kuyika manambala, ndipo kumayenda mokhazikika ndikulephera kwakanthawi kochepa pantchito, kuwongolera magwiridwe antchito a batch product marking ndikuthandizira kulimbikitsa kachulukidwe kake.

④ Zosinthika kwambiri

Ikhoza kusintha ku zipangizo zosiyanasiyana ndi mawonekedwe a workpieces kuti alembe, ndipo akhoza stably chizindikiro lathyathyathya ndi yaing'ono yokhota workpieces zopangidwa ndi zitsulo ndi zinthu zina sanali zitsulo, kukwaniritsa chodetsa zosowa zosiyanasiyana mankhwala manambala siriyo.

Comprehensive ubwino mzere kupanga

✅ Njira yodzichitira yokha: imachepetsa kulowererapo pamanja ndikuchepetsa chiwopsezo cha zolakwika.

✅ Kuwongolera kolondola kwambiri: kuyang'anira mosamalitsa pamlingo uliwonse kuti muwonetsetse kuti chiyero cha midadada yasiliva ndi ≥ 99.99%.

✅ Zosinthika komanso zosinthika: magawo osinthika kuti agwirizane ndi mafotokozedwe osiyanasiyana (1kg/5oz/100g, etc.)

✅ Imagwirizana ndi miyezo yapadziko lonse lapansi: imakwaniritsa zofunikira zamakampani monga ISO.

mapeto

Mzere wopangira siliva wa Hasung wasanduka njira yothetsera zitsulo zamtengo wapatali zopangira zitsulo, chifukwa cha granulator yogwira mtima, kupanga makina opangira vacuum ingot, kudziwika bwino kwa makina osindikizira, komanso kufufuza kwathunthu kwa makina osindikizira nambala. Kaya mukugulitsa mipiringidzo yasiliva, zida zasiliva zamafakitale, kapena zosonkhanitsa zapamwamba, mzere wopangawu ukhoza kupereka zinthu zokhazikika komanso zapamwamba zasiliva.

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. ndi kampani yopanga makina yomwe ili kum'mwera kwa China, mumzinda wokongola komanso womwe ukukula mwachangu kwambiri, Shenzhen. Kampaniyo ndi mtsogoleri waukadaulo pankhani ya zida zotenthetsera ndi kuponyera zitsulo zamtengo wapatali ndi mafakitale azinthu zatsopano.

Chidziwitso chathu champhamvu muukadaulo wopangira zinthu zopanda mpweya chimatithandizanso kutumikira makasitomala amafakitale popanga chitsulo chopangidwa ndi zitsulo zambiri, platinamu-rhodium alloy yofunikira kwambiri, golide ndi siliva, ndi zina zotero.

Tel: +86 17898439424

Imelo: sales@hasungmachinery.comndi

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115