Quality Best High Quality Platinum Vacuum Melting Furnace Rhodum Bullion Casting Machine Manufacturer | Hasung

High Quality Platinum Vacuum Melting Furnace Gold Bullion Casting Machine Silver Bar Vacuum Casting System compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Hasung summarizes the defects of past products, and continuously improves them. The specifications of High Quality Platinum Vacuum Melting Furnace Gold Bullion Casting Machine Silver Bar Vacuum Casting System can be customized according to your needs.

Best High Quality Platinum Vacuum Melting Furnace Silver Bullion Casting Machine compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Hasung summarizes the defects of past products, and continuously improves them. The specifications of Best High Quality Platinum Vacuum Melting Furnace Silver Bullion Casting Machine can be customized according to your needs.

High quality vacuum melting furnace gold silver bullion and ingot casting machine has won high attention and praise from customers.Technology is applied to better meet market demand.It will surely accommodate customers' unique temperament and taste.

About Hasung

Shenzhen Hasung Precious Metals Equipment Co., Ltd. is a mechanical engineering company located in the south of China, in the beautiful and the most fastest economic growing city, Shenzhen. The company is a technological leader in the area of heating and casting equipment for the precious metals and new materials industry. Our strong knowledge in vacuum casting technology further enables us to serve industrial customers to cast high-alloyed steel, high vacuum required platinum-rhodium alloy, gold and silver, etc. Our mission is to build the most innovative heating and casting equipment for precious metal manufacturing and gold jewellery industry, providing customers with the highest reliability in your daily operations and the best quality. We are acknowledged in the industry as a technology leader. What we're deserved to be proud is our vacuum and high vacuum technology is the best in China. Our equipment, manufactured in China, is made of highest-quality components, apply worldwide famous brands components such as Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, etc. Hasung has proudly served the precious metal casting & forming industry with vacuum pressure casting equipment, continuous casting machine, high vacuum continuous casting equipment, vacuum granulating equipment, induction melting furnaces, gold silver bullion vacuum casting machine, metal powder atomizing equipment, etc. Our R & D department is always working on developing casting and melting technologies to suit our ever changing industry for the New Materials industry, Aerospace, Gold Mining, Metal Minting Industry, Research laboratories, Rapid Prototyping, Jewellery, and Artistic Sculpture. We do provide precious metals solutions for customers. We uphold the principle of "integrity, quality,cooperation, win-win" business philosophy,committed to creating first-class products and services. We always believe that technology changes the future. We specialize in designing and developing custom finishing solutions. Committed to provide precious metal casting solutions, coin minting solution, platinum, gold and silver jewellery casting solution, bonding wire making solution, etc. Hasung is looking for partners and investors for precious metals to develop technological innovation bringing outstanding return on investment. We are a company who only makes high end quality equipment, we don't take price as priority, we take value for customers.

Company Advantages

Our machines enjoy two years warranty.

With first class level quality self-manufactured machines, enjoy high reputation.

It is extensively used in precious metals refining, precious metals smelting, precious metals bars, beads, powders trding, gold jewellery, etc.

We select raw material suppliers carrying the certificates that 100% guarantee the materials and apply world famous brands components such as Mitsubishi, Panasonic, SMC, Simens, Schneider, Omron, etc.

Shenzhen Hasung Precious Metals Equipment Co., Ltd relying on strong innovation ability and firm R&D perseverance, successfully developed High quality vacuum melting furnace gold silver bullion and ingot casting machine. Technological innovation is the fundamental reason for Shenzhen Hasung Precious Metals Equipment Co., Ltd to achieve sustainable development. Next,Shenzhen Hasung Precious Metals Equipment Co., Ltd will introduce more outstanding talents, invest more research and development funds, and improve market competitiveness.

SPECIFICATIONS:

| Model No. | HS-PGV1 | HS-PGV2 | HS-PGV4 |

| Voltage | 380V, 50/60Hz, 3 phases | ||

| Power | 15KW | 15KW | 20KW |

| Capacity (Pt) | 1kg | 2kg | 4kg |

| Casting Time | 3-5 minutes | 3-5 minutes | 3-5 minutes |

| Application Metals | Platinum, Palladium | ||

| Max. Temp | 2100°C | ||

| Casting product | Customized mould (tilting pouring type into the mould) | ||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||

| Control system | Taiwan Weinview / Siemens PLC Touch Panel intelligent control system | ||

| Inert gas | Nitrogen / argon | ||

| Cooling type | Water chiller or Running water | ||

| Vacuum pump | High vacuum level vacuum pump (included) | ||

| Induction Heating Technology | Germany IGBT Induction Heating | ||

| Dimension | 1460X720X1060mm | ||

| Weight | Approx. 360kg | ||

Company Advantages

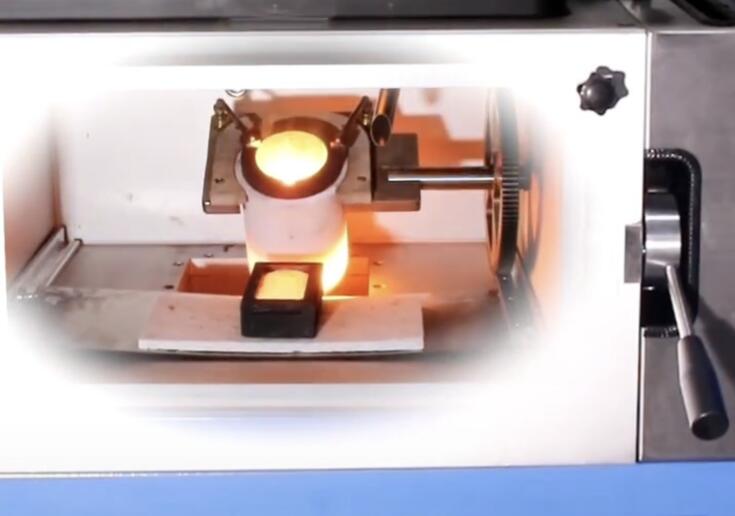

#The Art of Melting Platinum Bars: An Inside Look at Vacuum Induction Furnaces

Platinum is a precious metal known for its rarity and unique properties, attracting the attention of jewelers, investors and industrial manufacturers. One of the most efficient methods of melting platinum strips is using a vacuum induction furnace. This blog will explore how platinum bars are melted under vacuum induction conditions, the advantages of this method and the complex processes involved.

## Learn about vacuum induction furnaces

Before delving into the melting process, it is necessary to understand what a vacuum induction furnace (VIF) is. A VIF is a specialized furnace that uses electromagnetic induction to heat and melt metal in a controlled vacuum environment. This method is particularly beneficial for melting high-value metals such as platinum, as it minimizes contamination and oxidation, ensuring the purity of the final product.

### Components of vacuum induction furnace

A typical vacuum induction furnace consists of several key components:

1. **Induction Coil**: This is the heart of the stove, where the electromagnetic field is generated. The coil is usually made of copper and is designed to create a magnetic field that induces an electric current in the metal.

2. **Crucible**: The crucible is where platinum bars are placed for melting. It is usually made of materials that can withstand high temperatures and resist chemical reactions, such as graphite or ceramic.

3. **Vacuum Chamber**: The entire melting process occurs in a vacuum chamber, which is essential to prevent oxidation and contamination. Use a high-performance pump to create a vacuum that removes air and other gases from the room.

4. **Control System**: Modern VIF is equipped with an advanced control system that monitors temperature, pressure and other parameters to ensure optimal melting conditions.

## The melting process of platinum bars

Now that we have a basic understanding of vacuum induction furnaces, let's explore the step-by-step process of melting a platinum strip.

### Step 1: Preparation

Before melting, platinum bars must be prepared. This includes cleaning the rods to remove any surface contaminants such as oil or dirt. The crucible is also cleaned and preheated to ensure it can withstand the high temperatures required to melt the platinum.

### Step 2: Load the Crucible

After the preparation is complete, place the platinum rod into the crucible. The crucible is then placed inside the induction coil within the vacuum chamber. Take care to ensure that the rods are evenly distributed to promote even heating.

### Step 3: Create a vacuum

After the crucible is loaded, the vacuum chamber is sealed and the air is removed using a high-performance pump. The goal is to create a vacuum environment that reduces the presence of oxygen and other gases that can cause the platinum to oxidize during the melting process.

### Step 4: Induction Heating

Once a vacuum is established, the induction coil is energized. The electromagnetic field generated by the coil induces an electric current in the platinum bar, causing the platinum bar to heat up rapidly. Temperatures can reach over 1,700 degrees Celsius (3,092 degrees Fahrenheit), which is necessary to melt platinum.

### Step 5: Monitor

Throughout the melting process, the control system continuously monitors temperature and vacuum levels. Operators can make real-time adjustments to ensure the platinum melts evenly and reaches the desired temperature without overheating.

### Step 6: Pour the molten platinum

Once the platinum is completely melted, it can be poured into molds. Carefully open the vacuum chamber and pour the molten platinum into the prepared mold, where it cools and solidifies into the desired shape.

### Step 7: Cool and Finish

After pouring, the mold is allowed to cool and the solidified platinum rod is removed. The final step involves finishing processes such as polishing and quality checks to ensure the platinum meets industry standards.

## Advantages of vacuum induction melting of platinum

Using a vacuum induction furnace to melt platinum strips has several advantages:

1. Purity: The vacuum environment minimizes the risk of oxidation and contamination, ensuring that the final product is of high purity.

2. Efficiency: Induction heating is highly efficient and can melt quickly and reduce energy consumption compared to traditional melting methods.

3. Control: The ability to monitor the melting process in real-time results in consistent results and high-quality output.

4. VERSATILITY: Vacuum induction furnaces can be used to melt a variety of metals, making them a versatile tool in metal processing and manufacturing.

In conclusion

Melting platinum bars under vacuum induction conditions is a complex process that combines advanced technology and skilled craftsmanship. The use of vacuum induction furnaces not only improves the purity and quality of molten platinum, but also simplifies the entire melting process. As the industry continues to grow, the demand for high-quality platinum products will only increase, making understanding this melting technology even more important. Whether you're a jeweler, investor, or just a metal enthusiast, appreciating the intricate process of platinum melting can deepen your understanding of this precious metal and its applications.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115