UHasung ungumkhiqizi womshini wokubumba nokuncibilikisa izinsimbi eziyigugu ochwepheshe kusukela ngo-2014.

Iyini imishini ye-metal powder water atomization? Isebenza kanjani?

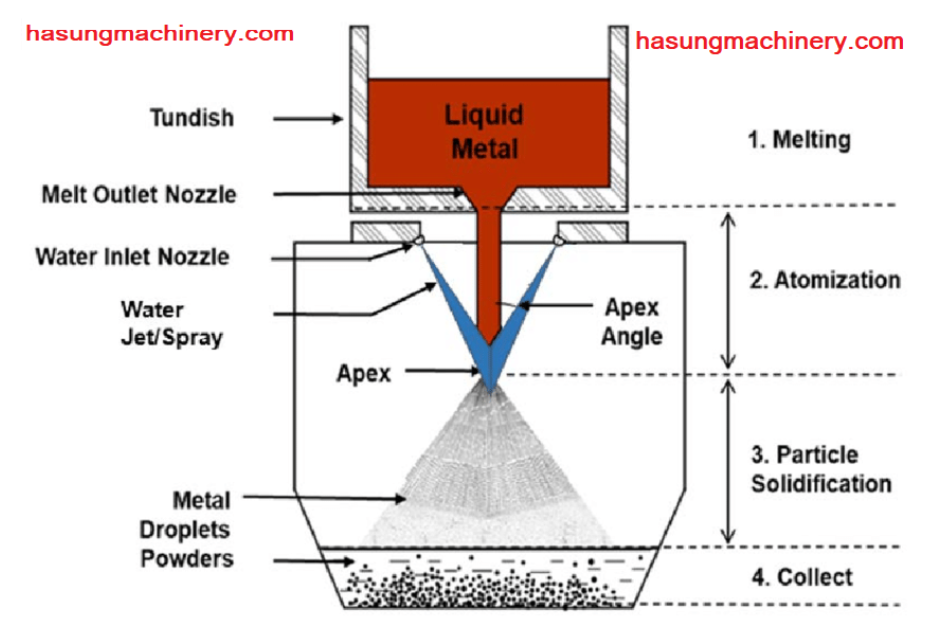

Le mishini isetshenziswa kakhulu ekwenzeni i-powder yensimbi noma i-granule ku-atomization. Ikamelo ngendlela ye-atomization yamanzi enomfutho ophezulu ngemva kwensimbi noma i-alloy yensimbi. Ingancibilikiswa ngaphansi kwendawo yokuvikela igesi noma indawo evamile yomoya. Izindleko zokusebenza zokukhiqiza umshini kanye ne-powder ziphansi. I-Metal Powder Water Atomization Equipment uhlobo lwendlela yokulungiselela i-powder lapho insimbi noma uketshezi oluhlanganisiwe luhlukaniswa khona lube yizicucu ezincane ngokushukuma okusheshayo koketshezi (i-atomization medium) noma ezinye izindlela, kulandelwa ukwakheka kube yi-powder enamandla. Noma yiziphi izinto ezingabumba uketshezi zingaguqulwa zibe yi-atom futhi zibe yi-powder. Indlela ye-atomization yamanzi enomfutho ophezulu ingakhiqiza ngezimali nangokusebenza kahle i-MIM metal amalgam powder, i-powder yensimbi ephathwayo ehlukile, i-fast steel powder, i-value metal powder, i-combined powder esekelwe ethusi, kanye ne-super combination Powder, njalo njalo. Ezisetshenziswa kakhulu yi-gas atomization Equipment kanye ne-water atomization Equipment. Ngesikhathi sokusebenza kwe-atomization powder, ncibilikisa izinto zensimbi ezingacolisisiwe zibe yi-amalgam fluid efanelekile (ngokuvamile ishiswe kakhulu ku-100-150 ℃) nge-heater kagesi noma i-heater yokwamukela, bese ifakwa ku-tundish phezu kwe-atomizing spout. Uketshezi oluhlanganisiwe luphuma ekuvulekeni kokuchitheka engxenyeni engezansi ye-tundish, futhi uma ludlula e-spout, lufakwa kuma-atomial beads lapho luzwa umoya ovunguzayo noma umsinga wamanzi. Amaconsi e-atomi aqiniswa ngokushesha abe yi-composite powder ekamelweni elivaliwe le-atomizing. Ngokuvamile, izinhlayiya ze-atomial powder zegesi elingasebenzi ziyindilinga, zinokuqukethwe okuphansi kwe-oxygen (ngaphansi kuka-100 × 10), futhi zingenziwa kalula zibe izinto ezihlanganisiwe ngobuchwepheshe be-thermoforming, (isibonelo, ukucindezela okushisayo kwe-isostatic). Izinhlayiya ze-atomial powder ze-atomial ngokuvamile ziyizimo ezingalindelekile ezinokuqukethwe okuphezulu kwe-oxygen (ngaphezu kuka-600 × 10) futhi kufanele ziqiniswe. Zinokucindezelwa okukhulu futhi zingacindezelwa kubanda zibe izingxenye zemishini. [ubunikazi besihloko = "okunamathiselwe_899" ububanzi = "850"]

Imishini Yokwenza Amanzi Athomu Yensimbi[/amagama] Isimiso Sokusebenza: Indlela ehilelekile ekulethweni kwempuphu yensimbi nge-atomization yamanzi, imishini yokucubungula i-pummeling inomlando omude. Ezikhathini zakudala, abantu bathululela insimbi ewuketshezi emanzini bayiqhumisa ibe yizinhlayiya zensimbi ezincane, ezazisetshenziswa njengezingxenye ezingacolisisiwe zokwenza insimbi; kuze kube manje, kunabantu abathululela i-lead ewuketshezi ngqo emanzini ukuze benze izibhamu ze-lead. Isu lokugaya i-atomization yamanzi lisetshenziselwa ukwenza i-powder ehlanganisiwe ewuketshezi. Isiqondiso somjikelezo sifana nokuvumela amanzi ukuthi aqhumise insimbi ewuketshezi, kodwa umkhiqizo owonakalisayo uthuthuke kakhulu. Ukuze kwenziwe i-powder ehlanganisiwe ewuketshezi nge-atomization yamanzi, igolide eliwuketshezi kufanele lincibilikiswe ku-heater kuqala, bese igolide eliwuketshezi kufanele lishiswe kakhulu cishe ngama-degrees angu-50. Bese, ngaleso sikhathi, lifakwe ku-tundish. Qala i-siphon yamanzi enomfutho ophezulu ngaphambi kokuba uketshezi lwegolide lufakwe, bese uvumela i-atomization yamanzi enomfutho ophezulu ukuthi iqale umsebenzi. Uketshezi lwegolide oluse-tundish ludlula ebhareni bese lungena ku-atomizer nge-spout echithekayo engxenyeni engezansi ye-bundle. I-atomizer iyithuluzi elibalulekile lokuletha i-powder yegolide engcolile ene-high tension water fog. Uhlobo lwe-atomizer luhlotshaniswa nekhono elibi le-powder yensimbi. Ngaphansi komsebenzi wamanzi acindezelwe kakhulu avela ku-atomizer, uketshezi lwegolide luhlala luqhekeka lube ama-beads amahle, awela ku-fluid epholile kudivayisi, bese eqiniswa ngokushesha abe yi-amalgam powder. Enkambisweni evamile ye-atomization yamanzi acindezelwe kakhulu yokuletha i-powder yensimbi, i-powder yensimbi ingaqoqwa njalo, kodwa inani elincane le-powder yensimbi lizolahleka ngamanzi acindezelwe. Ukuze kutholakale i-atomization yamanzi acindezelwe kakhulu, umkhiqizo we-atomized upakishwa kudivayisi ye-atomization, usheshiswe, uhlungwe, (uma kubalulekile, ungomiswa kahle, ngokuvamile uthunyelwa ngqo ohlelweni olulandelayo.) ukuze uthole i-Alloy powder enhle, ngeke kube khona ukuntuleka kwe-amalgam powder kulo lonke umjikelezo. Kodwa inani elincane le-powder yensimbi lizolahleka ngamanzi acindezelwe. Ukuze kutholakale i-atomization yamanzi enomfutho ophezulu, into e-atomized ipakishwa ku-atomization gadget, isheshiswe, ihlungwe, (uma kubalulekile, ingase yomiswe kahle, ngokuvamile ithunyelwe ngqo kusuka ohlelweni olulandelayo.) ukuze kutholakale i-Alloy powder enhle, ngeke kube khona ukuntuleka kwe-amalgam powder kulo lonke umjikelezo. Kodwa inani elincane le-metal powder lizolahleka ngamanzi ane-atomized. Ukuze kutholakale i-atomization yamanzi enomfutho ophezulu, into e-atomized ipakishwa ku-atomization gadget, isheshiswe, ihlungwe, (uma kubalulekile, ingase yomiswe kahle, ngokuvamile ithunyelwe ngqo kusuka ohlelweni olulandelayo.) ukuze kutholakale i-Alloy powder enhle, ngeke kube khona ukuntuleka kwe-amalgam powder kulo lonke umjikelezo.

Ukuhlelwa okuphelele kwehadiwe yokwenza amanzi ngempuphu yensimbi kuqukethe izingxenye ezilandelayo: Ingxenye yokuncibilikisa: Ungakhetha isithando sokushisa insimbi esiphakathi nendawo noma isithando sokushisa insimbi esivame kakhulu. Umthamo wesithando uncike kumthamo wokucubungula wempuphu yensimbi. Ungakhetha isithando sokushisa esingu-50 kg noma isithando sokushisa esingu-20 kg. Ingxenye yokwenza amanzi nge-atomization: Le ngxenye yemishini iyimishini engeyona ejwayelekile, okufanele iklanywe futhi ihlelwe ngokwezimo zendawo yomenzi, ikakhulukazi kufaka phakathi i-tundish: lapho i-tundish ikhiqizwa ebusika, idinga ukushiswa kusengaphambili; I-Atomizer: I-atomizer ithinta amanzi anomfutho ophezulu avela empompini yamanzi enomfutho ophezulu ngesivinini esinqunyiwe kanye ne-engeli ngokumelene noketshezi lwegolide oluvela ku-tundish, luyiphule ibe amaconsi ensimbi. Ngaphansi kokucindezela okufanayo kwepompo, inani lempuphu yensimbi ecolekile ngemva kokwenza amanzi nge-atomization lihlobene nokusebenza kahle kwe-atomization kwe-atomizer; isilinda se-atomization: yindawo lapho i-alloy powder ifakwa khona i-atomization, ichotshozwe, ipholiswe futhi iqoqwe. Ukuze kuvinjelwe i-superfine alloy powder ukuthi ingalahlekelwa ngamanzi, i-alloy powder elungisiwe kufanele ivunyelwe ukuthi ime isikhathi esithile ngemva kokuyigaya, bese ifakwa ebhokisini lokwamukela i-powder. [embed]https://youtu.be/2XDz2LGFhkI[/embed] Ingxenye yokucubungula ngemuva: ibhokisi lokuqoqa i-powder: elisetshenziselwa ukuqoqwa kwe-atomized alloy powder, ukuhlukaniswa nokususwa kwamanzi amaningi; isithando sokomisa: ukomisa i-alloy powder emanzi ngamanzi; umshini wokuhlola: ukuhlola i-alloy powder, I-alloy powder eqinile engahlangabezani nezimfuneko ingasetshenziswa njengezinto zokuncibilikisa ukuze iphinde incibilikiswe futhi i-atomized. Imishini yokwenza i-atomization yamanzi ye-metal powder enomfutho ophezulu inezici ezilandelayo: 1-Ingasetshenziswa ezinsimbini eziningi kanye ne-combination powders, futhi izindleko zokudala ziphansi. 2-Ingahlela i-subspherical powder noma i-sporadic powder. 3-Ngenxa yokuqinisa ngokushesha kanye nokungabikho kokuhlukaniswa, ama-amalgam powder amaningi ahlukile angalungela. 4-Usayizi we-molecule ye-powder ungafika endaweni edingekayo ngokushintsha uhlelo lokufaka.

Imishini Yokwenza Amanzi Athomu Yensimbi

Ukuze uthole ulwazi olwengeziwe sicela usithumelele i-imeyili:info@hasungmachinery.com Iwebhusayithi: https://hasungmachinery.com/__wp/

I-Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yinkampani yobunjiniyela bemishini etholakala eningizimu yeShayina, edolobheni elihle nelikhula ngokushesha kwezomnotho, iShenzhen. Le nkampani ingumholi kwezobuchwepheshe emkhakheni wemishini yokushisa nokukhipha izinsimbi eziyigugu kanye nemboni yezinto ezintsha.

Ulwazi lwethu oluqinile kubuchwepheshe bokuphonswa kwe-vacuum lusenza sikwazi ukukhonza amakhasimende ezimboni ukuze afake insimbi exutshwe kakhulu, i-platinum-rhodium alloy edingekayo nge-vacuum ephezulu, igolide nesiliva, njll.

Ucingo: +86 17898439424

I-imeyili: sales@hasungmachinery.com...

WhatsApp: 0086 17898439424

Ikheli: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, Shenzhen, China 518115