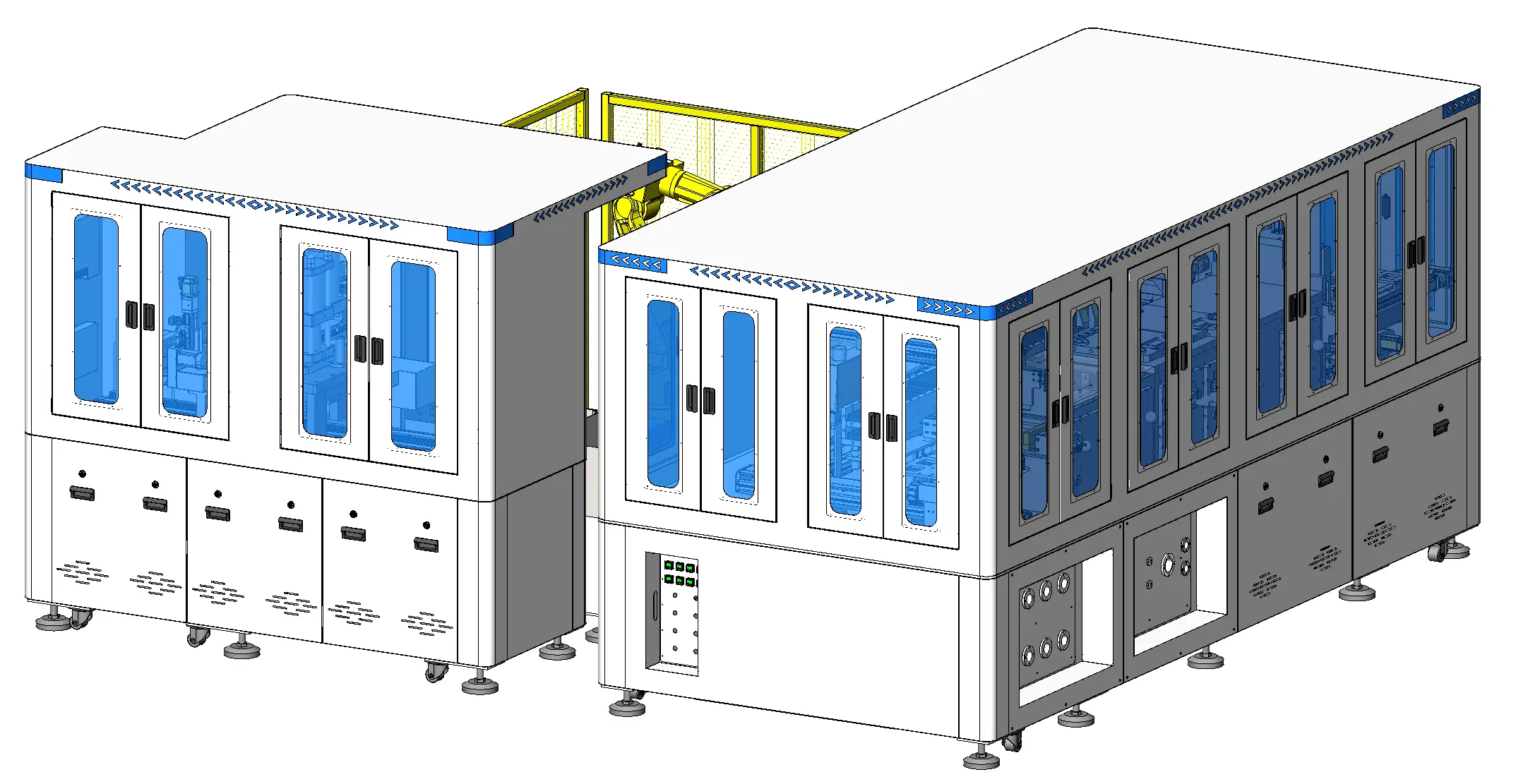

Hasung - Tunnel Furnace Automatic Vacuum Gold Ingot Casting System Automatic Gold Bullion Casting Production Line

1000 OZ 30kg fully automatic vacuum gold ingot casting system Automatic gold bullion production line with excellent performance and excellent quality, it has won the trust and support of customers, and has gained higher and higher recognition and reputation in the market.

Shenzhen Hasung Precious Metals Equipment Co., Ltd always upholds the principle of'complementary advantages, mutual benefit and win-win', and has established long-term cooperative relations with many well-known domestic and foreign companies. Our company has been investing heavily in R&D and upgrades of technologies. This has given initial results eventually. As 1000 OZ 30kg fully automatic vacuum gold ingot casting system Automatic gold bullion production line advantages are discovered continually, it has been widely used in the field(s) of Metal Casting Machinery. To meet various needs of customers, Shenzhen Hasung Precious Metals Equipment Co., Ltd supports customized 1000 OZ 30kg fully automatic vacuum gold ingot casting system Automatic gold bullion production line.

The First-Class Quality and Technology for Precious Metals Equipment Manufacturer in China.

With automatic casting system, average 1 minute for 1 piece 1kg gold bar finished.

Product specification:

|

Model No.

|

HS-AVF260-1

|

HS-AVF260-15

|

HS-AVF260-30

|

||

|

Automatic Tunnel Furnace Gold Bar Vacuum Casting System

|

|||||

|

Voltage

|

380V ,50/60Hz

|

||||

|

Total Power

|

120KW

|

150KW

|

200KW

|

||

|

Max Temp

|

1600°C

|

||||

|

Shielding Gas

|

Argon / Nitrogen

|

||||

|

Temperature Accuracy

|

±1°C

|

||||

|

Capacity (gold)

|

1kg/pcs, 4 or 5pcs per mould

|

15kg/pcs

|

30kg/pcs

|

||

|

Application

|

Gold, Silver, Copper

|

||||

|

Vacuum

|

German Vacuum Pump, Vacuum degree-100KPA (optional)

|

||||

|

Operation method

|

One-key operation to complete the entire process, POKA YOKE foolproof system

|

||||

|

Control system

|

10" Taiwan Weinview/Siemens PLC+Human-machine interface intelligent control system (included)

|

||||

|

Cooling type

|

Water chiller(sold separately) or Running water

|

||||

|

Dimensions

|

6500X4500X2500mm

|

||||

|

Weight

|

2800KG

|

3500KG

|

4000KG

|

||

Details Images

Gold bar production: the best solution for automated production

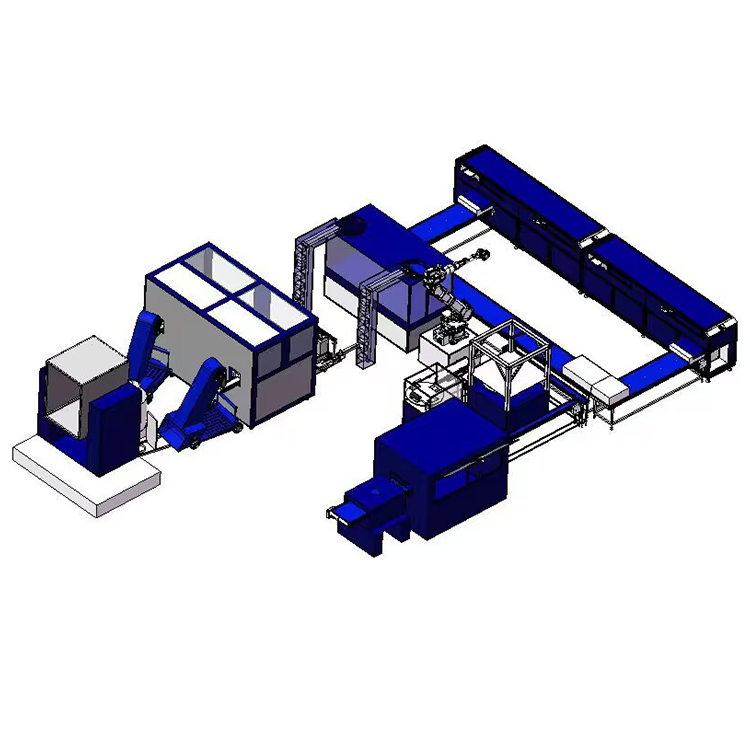

Gold bar production is a complex process that requires precision and efficiency to ensure a high-quality output. A key aspect of this process is the use of production line tunnel furnaces, which play an important role in the automated production of gold bars. In this article we will explore the best solutions for automated gold bar production, focusing on integrating a production line tunnel furnace into the production process.

The production of gold bars involves multiple stages, including melting and casting the gold into bars or ingots. In order to achieve a high level of automation and efficiency in this process, the use of a production line tunnel furnace is essential. This type of furnace is designed to provide a continuous and controlled environment for the melting and casting of gold, ensuring consistent quality and yield.

One of the main advantages of using a production line tunnel furnace to produce gold bars is its ability to process large quantities of material with minimal human intervention. This is especially important in high-volume production environments, where the efficiency of the production process directly affects the overall throughput and profitability of the operation.

Integrating a production line tunnel furnace into the gold bar production process offers several advantages, including:

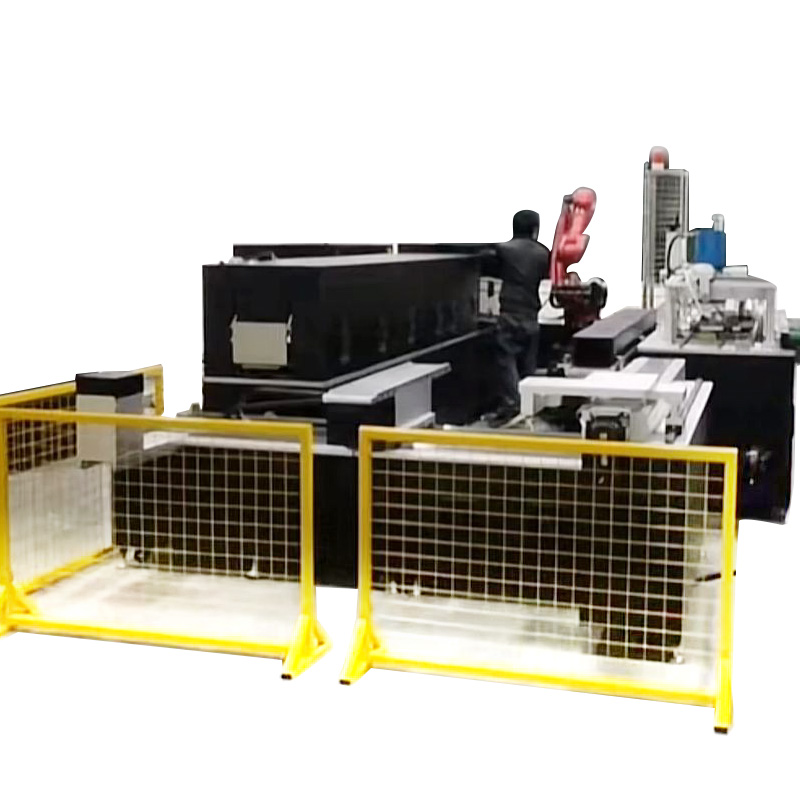

1. Stable quality: The controlled environment of the tunnel furnace ensures that gold is melted and cast under optimal temperatures and conditions, resulting in stable quality of the final gold and silver product.

2. Improve efficiency: The continuous operation of the production line tunnel furnace can achieve high material throughput and reduce the time and labor required for the production process.

3. Cost savings: By automating the production process using tunnel furnaces, companies can reduce labor costs and minimize material waste, thereby saving on the overall cost of gold bar production.

4. Enhanced safety: The use of tunnel furnaces in production lines minimizes workers’ exposure to high-temperature processes and improves the overall safety of the production environment.

When considering the best solution for automated gold bar production, it is important to evaluate the specific requirements of the production process and select a production line tunnel furnace suitable to meet these needs. Factors to consider when selecting a tunnel furnace for gold bullion production include:

1. Capacity: The furnace should have the ability to handle expected material volumes to ensure production needs are met efficiently.

2. Control system: Advanced control systems are crucial to maintaining precise mesuring and process control, helping to ensure stable quality of gold bar output.

3. Energy efficiency: Production line tunnel furnaces with energy-saving features help reduce operating costs and minimize environmental impact.

4. Maintenance and Support: Choosing a furnace from a reputable manufacturer with a strong support network ensures ready access to maintenance and technical assistance, minimizing downtime and production interruptions.

In addition to the production line tunnel furnace, the overall automation of the gold bar production process can be further improved by integrating advanced technologies such as robots, material handling systems, and real-time monitoring systems. These technologies work in conjunction with the tunnel furnace to create a seamless, efficient production environment.

In summary, the best solution for automated gold bar production is to integrate a production line tunnel furnace into the production process. The furnace offers a range of benefits, including consistent quality, improved efficiency, cost savings and enhanced safety. When selecting a tunnel furnace for gold bullion production, it is important to consider factors such as capacity, control systems, energy efficiency, and maintenance and support. By leveraging the capabilities of the production line tunnel furnace and advanced automation technology, the company can achieve high efficiency and precision in gold bar production, ultimately gaining a competitive advantage in the market.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115