From Wax Model to Dazzling Finished Jewelry: A Complete Process Breakdown

Jewelry, as a symbol of luxury and art, has a production process that remains largely unknown to many. Behind every exquisite piece lies a precise and efficient production line—the jewelry tree wax casting line. This process blends traditional craftsmanship with modern technology, where each step, from the initial wax model to the final polished product, is crucial. This article will take you through each stage of this production line, unveiling the "magic chain" of jewelry manufacturing.

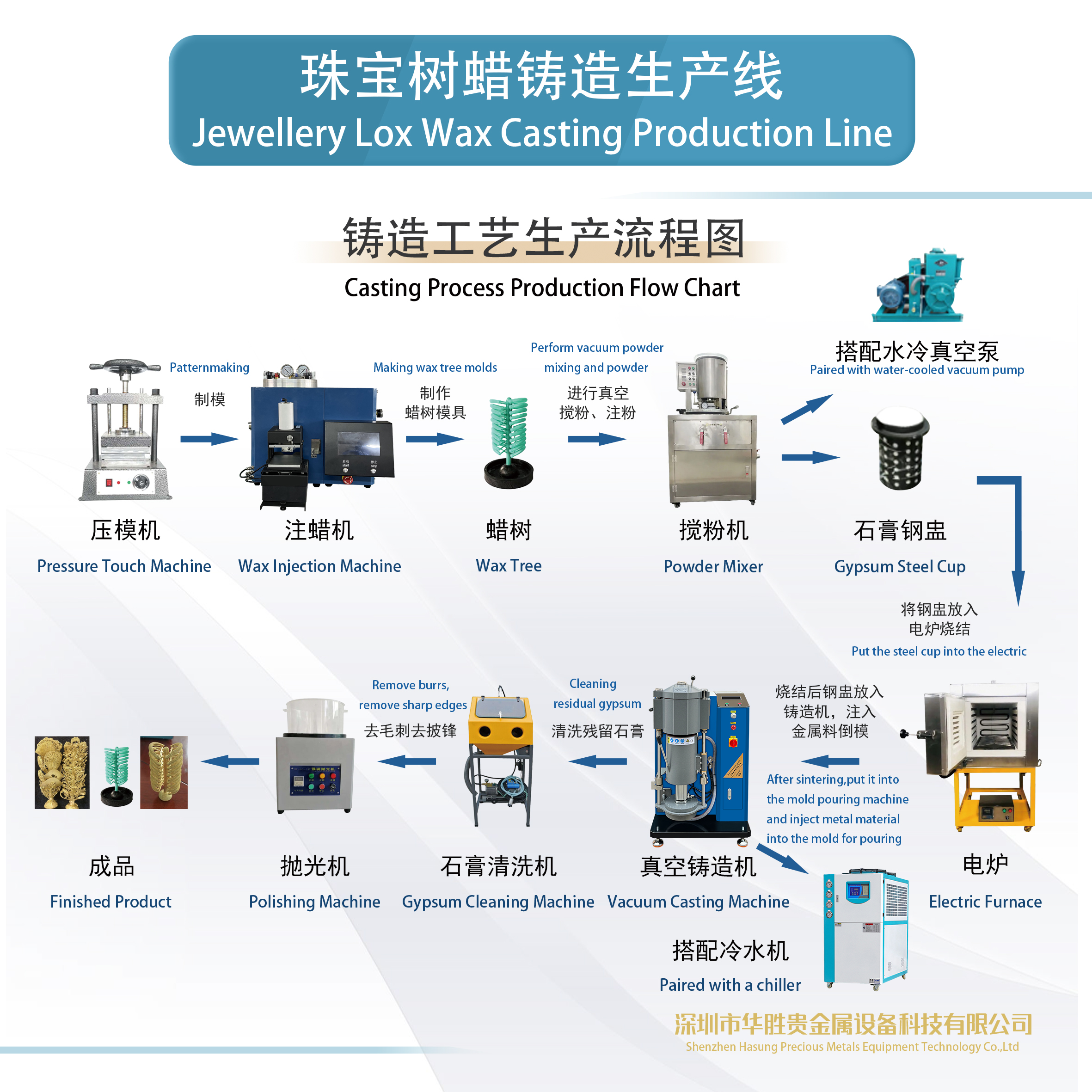

1. Die Press: The Starting Point of Casting, the Foundation of Precision

Function: The die press is the first step in jewelry manufacturing, primarily used to create metal molds (steel dies). The designer’s original model is replicated into a high-precision metal mold, ensuring that subsequent wax models retain every detail and dimension.

Key Techniques:

(1)High-hardness steel is used to ensure mold durability.

(2)Hydraulic or mechanical pressure ensures sharp details.

(3)Reusable molds improve production efficiency.

Why It Matters?

If the mold lacks precision, the wax models and metal castings will suffer from deformities or lost details, compromising the final product’s quality.

2. Wax Injector: Breathing Life into the Design

Function: Molten wax is injected into the metal mold to form wax models after cooling. These wax models serve as the "prototypes" for casting, directly influencing the jewelry’s final shape.

Key Techniques:

(1)Low-shrinkage wax prevents deformation.

(2)Precise temperature and pressure control avoid bubbles or defects.

(3)Automated injectors enhance consistency and reduce human error.

Why It Matters?

The wax model’s precision determines the jewelry’s appearance—any flaw will be magnified in the metal casting.

3. Wax Tree Assembly: Creating a "Jewelry Forest"

Function: Multiple wax models are connected via wax sprues to form a "wax tree," optimizing casting efficiency. A single tree can hold dozens or even hundreds of wax models, enabling mass production.

Key Techniques:

(1)The wax tree structure must be scientifically designed for even metal flow.

(2)Proper spacing between wax models prevents interference during casting.

Why It Matters?

An efficient wax tree reduces metal waste and improves casting success rates.

4. Powder Mixer: Perfecting the Plaster Slurry

Function: Special plaster powder is mixed with water to form a smooth slurry, which coats the wax tree to create the casting mold.

Key Techniques:

(1)The plaster must have high heat resistance and porosity.

(2)Thorough mixing prevents bubbles that weaken the mold.

(3)Vacuum degassing further enhances plaster quality.

Why It Matters?

The plaster mold’s strength and porosity affect metal flow and the casting’s surface finish.

5. Investment Flask: The High-Temperature "Protective Shell"

Function: The plaster-coated wax tree is placed in a steel flask and heated to melt away the wax, leaving a cavity for metal casting.

Key Techniques:

(1)Gradual temperature increases prevent plaster cracking.

(2)Complete wax removal ensures metal purity.

Why It Matters?

The quality of this step determines whether the metal fully fills the wax mold’s cavity.

6. Electric Furnace: Melting and Purifying Metal

Function: Precious metals like gold and silver are melted and purified to ensure fluidity and purity.

Key Techniques:

(1)Precise temperature control (e.g., gold melts at ~1064°C).

(2)Flux additives improve metal flow.

(3)Inert gases (e.g., argon) prevent oxidation.

Why It Matters?

Metal purity directly impacts the final product’s color and strength.

7. Vacuum Caster: Precision Metal Pouring

Function: Molten metal is injected into the plaster mold under vacuum to ensure complete filling of fine details and minimize bubbles.

Key Techniques:

(1)Vacuum reduces bubbles, enhancing density.

(2)Centrifugal force aids in thorough filling.

Why It Matters?

Vacuum casting minimizes defects like porosity, improving yield rates.

8. Plaster Removal System: Demolding and Initial Cleaning

Function: Cooled castings are extracted from the plaster mold, and residual plaster is removed via high-pressure water or ultrasonic cleaning.

Key Techniques:

(1)Controlled water pressure prevents damage to delicate structures.

(2)Ultrasonic cleaning reaches deep crevices for thorough removal.

Why It Matters?

Residual plaster can interfere with further processing and polishing.

9. Polishing Machine: Bestowing Radiant Brilliance

Function: Mechanical or electrolytic polishing removes burrs and oxidation, giving the jewelry a mirror-like shine.

Key Techniques:

(1)Material-specific polishing wheels and compounds are used.

(2)Automated polishers ensure consistency and reduce human error.

Why It Matters?

Polishing is the final "beautification" step, defining the jewelry’s visual appeal and texture.

10. Finished Product: From Production Line to Consumer

After these meticulous steps, a stunning piece of jewelry is born—whether a ring, necklace, or pair of earrings, each embodies precision and craftsmanship.

Conclusion: The Perfect Fusion of Technology and Art

The jewelry tree wax casting line is not just a manufacturing marvel but a harmonious blend of technology and artistry. From wax sculpting to metal casting and polishing, every step is vital. It’s this seamless coordination that makes each jewelry piece shine brilliantly, becoming a cherished work of art.

Next time you admire a piece of jewelry, remember the "magic chain" behind it—transforming wax into metal, roughness into radiance. This is the captivating essence of modern jewelry manufacturing.

You can contact us through the following ways:

Whatsapp: 008617898439424

Email: sales@hasungmachinery.com

Web: www.hasungmachinery.com www.hasungcasting.com

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115