Los ntawm Wax Model rau Dazzling Finished Jewelry: Ib qho kev ua tiav tiav

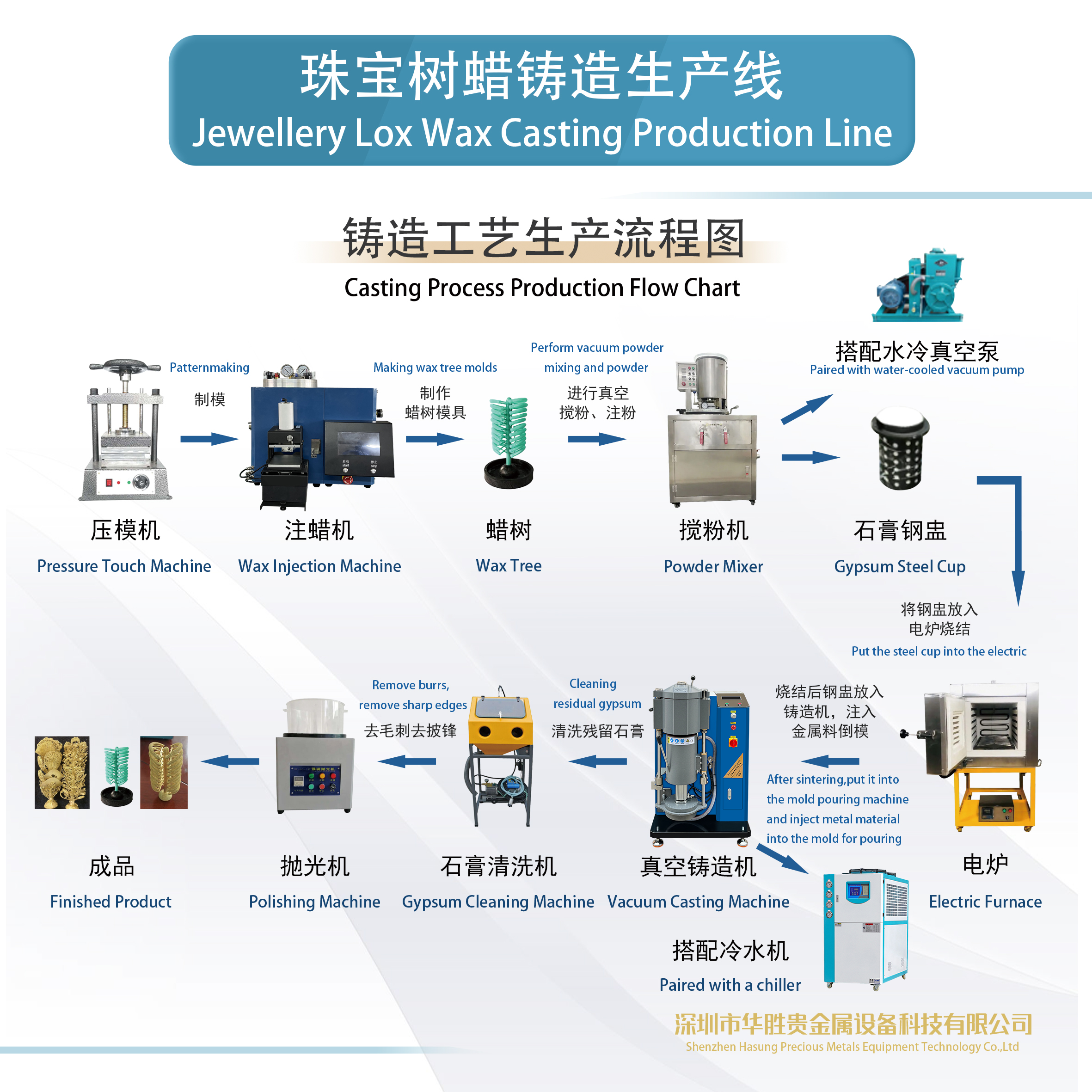

Cov hniav nyiaj hniav kub, ua lub cim ntawm cov khoom kim heev thiab kos duab, muaj cov txheej txheem tsim khoom uas tseem tsis tau paub txog ntau yam. Tom qab txhua qhov zoo nkauj yog cov kab ntau lawm thiab ua tau zoo - cov hniav nyiaj hniav kub ntoo ciab casting kab. Cov txheej txheem no muab cov tsoos craftsmanship nrog cov cuab yeej niaj hnub, qhov twg txhua kauj ruam, los ntawm cov qauv siv quav ciab mus rau qhov kawg polished khoom, yog qhov tseem ceeb. Kab lus no yuav coj koj mus rau txhua theem ntawm cov kab ntau lawm, nthuav tawm "cov saw hlau khawv koob" ntawm kev tsim cov hniav nyiaj hniav kub.

1. Die Xovxwm: Qhov Pib Taw Qhia ntawm Casting, lub hauv paus ntawm Precision

Muaj nuj nqi: Cov xovxwm tuag yog thawj kauj ruam hauv kev tsim cov hniav nyiaj hniav kub, feem ntau yog siv los tsim cov pwm hlau (steel dies). Tus tsim qauv tus qauv qub yog rov ua dua tshiab rau hauv cov pwm hlau zoo, kom ntseeg tau tias cov qauv siv quav ciab tom qab khaws txhua qhov nthuav dav thiab qhov ntev.

Cov txuj ci tseem ceeb:

(1) High-hardness steel yog siv los xyuas kom meej pwm durability.

(2) Hydraulic lossis mechanical siab kom paub meej meej.

(3) Reusable pwm txhim kho kev tsim khoom.

Vim li cas thiaj tseem ceeb?

Yog tias cov pwm tsis muaj qhov tseeb, cov qauv siv quav ciab thiab cov hlau castings yuav raug kev txom nyem los ntawm deformities los yog ploj cov ntsiab lus, cuam tshuam qhov kawg ntawm cov khoom zoo.

2. Wax Injector: Ua pa lub neej rau hauv kev tsim

Muaj nuj nqi: Molten wax yog txhaj rau hauv cov pwm hlau los tsim cov qauv siv quav ciab tom qab txias. Cov qauv siv quav ciab no ua rau "prototypes" rau casting, ncaj qha cuam tshuam cov hniav nyiaj hniav kub qhov kawg duab.

Cov txuj ci tseem ceeb:

(1) Tsawg-shrinkage ciab tiv thaiv deformation.

(2) Precise kub thiab siab tswj kom tsis txhob muaj npuas los yog tsis xws luag.

(3) Tsis siv neeg txhaj tshuaj txhim khu kev sib xws thiab txo tib neeg kev ua yuam kev.

Vim li cas thiaj tseem ceeb?

Cov qauv siv quav ciab qhov tseeb txiav txim siab cov hniav nyiaj hniav kub zoo li-txhua qhov tsis zoo yuav raug nthuav dav hauv cov hlau casting.

3. Tsob Ntoo Tsob Ntoo Los Ua Ke: Tsim ib "Ntiaj Tswb Vaj"

Muaj nuj nqi: Ntau cov qauv siv quav ciab txuas nrog cov khoom siv siv quav ciab los ua "cov ntoo siv quav ciab," optimizing casting efficiency. Ib tsob ntoo muaj peev xwm tuav tau kaum ob lossis ntau pua tus qauv siv quav ciab, ua kom muaj ntau lawm.

Cov txuj ci tseem ceeb:

(1) Cov qauv ntoo siv quav ciab yuav tsum tau tsim los rau kev tshawb fawb txawm tias hlau ntws.

(2) Kev sib nrug ntawm cov qauv siv quav ciab tiv thaiv kev cuam tshuam thaum lub sij hawm casting.

Vim li cas thiaj tseem ceeb?

Ib tsob ntoo wax zoo txo cov hlau pov tseg thiab txhim kho qhov ua tau zoo ntawm kev ua tiav.

4. Powder Tov Khoom: Ua kom tiav cov Plaster Slurry

Kev Ua Haujlwm: Cov hmoov plaster tshwj xeeb yog tov nrog dej los tsim cov slurry du, uas coats ntoo wax los tsim cov pwm pwm.

Cov txuj ci tseem ceeb:

(1) Lub plaster yuav tsum muaj cov cua kub tsis kam thiab porosity.

(2) Kev sib xyaw kom zoo tiv thaiv cov npuas uas ua rau pwm tsis muaj zog.

(3) Nqus degassing ntxiv txhim kho plaster zoo.

Vim li cas thiaj tseem ceeb?

Lub plaster pwm lub zog thiab qhov porosity cuam tshuam rau cov hlau ntws thiab casting qhov chaw tiav.

5. Peev Flask: Qhov Kub Kub "Tshuaj Tiv Thaiv"

Muaj nuj nqi: Lub plaster-coated ciab tsob ntoo yog muab tso rau hauv ib lub raj mis steel thiab rhuab kom yaj tawm cov quav ciab, tawm hauv kab noj hniav rau hlau casting.

Cov txuj ci tseem ceeb:

(1) Maj mam kub nce ntxiv tiv thaiv plaster tawg.

(2) Kev tshem tawm tag nrho ua kom cov hlau purity.

Vim li cas thiaj tseem ceeb?

Qhov zoo ntawm cov kauj ruam no txiav txim siab seb cov hlau puas puv cov quav pwm cov kab noj hniav.

6. Hluav taws xob rauv: Melting thiab Purifying Hlau

Muaj nuj nqi: Cov hlau zoo li kub thiab nyiaj yog melted thiab purified kom muaj fluidity thiab purity.

Cov txuj ci tseem ceeb:

(1) Tswj qhov kub thiab txias (piv txwv li, kub melts ntawm ~ 1064 ° C).

(2) Flux additives txhim kho hlau ntws.

(3) Inert gases (xws li, argon) tiv thaiv oxidation.

Vim li cas thiaj tseem ceeb?

Hlau purity ncaj qha cuam tshuam cov khoom kawg cov xim thiab lub zog.

7. Nqus Caster : Precision Hlau Pouring

Muaj nuj nqi: Molten hlau yog txhaj rau hauv lub plaster pwm hauv qab lub tshuab nqus tsev kom ua tiav cov ntsiab lus zoo thiab txo cov npuas.

Cov txuj ci tseem ceeb:

(1) Lub tshuab nqus tsev txo cov npuas, txhim kho qhov ntom ntom.

(2) Lub zog centrifugal pab ua kom tiav.

Vim li cas thiaj tseem ceeb?

Nqus casting minimizes qhov tsis xws luag xws li porosity, txhim kho tus nqi yield.

8. Plaster Tshem Tawm System: Demolding thiab Initial Cleaning

Muaj nuj nqi: Txias castings yog muab rho tawm los ntawm plaster pwm, thiab residual plaster yog tshem tawm ntawm high-pressure dej los yog ultrasonic tu.

Cov txuj ci tseem ceeb:

(1) Tswj dej siab tiv thaiv kev puas tsuaj rau cov qauv muag.

(2) Ultrasonic tu mus txog qhov tob tob rau kev tshem tawm tag nrho.

Vim li cas thiaj tseem ceeb?

Residual plaster tuaj yeem cuam tshuam nrog kev ua haujlwm ntxiv thiab polishing.

9. Polishing Tshuab: Muab Radiant Brilliance

Kev Ua Haujlwm: Kev siv tshuab lossis electrolytic polishing tshem tawm burrs thiab oxidation, muab cov hniav nyiaj hniav kub zoo li daim iav ci.

Cov txuj ci tseem ceeb:

(1) Cov khoom siv tshwj xeeb polishing log thiab cov khoom sib txuas yog siv.

(2) Automated polishers xyuas kom zoo ib yam thiab txo tib neeg kev ua yuam kev.

Vim li cas thiaj tseem ceeb?

Polishing yog qhov kawg "beautification" kauj ruam, txhais cov hniav nyiaj hniav kub qhov kev pom zoo thiab kev ntxhib los mos.

10. Cov khoom tiav: Los ntawm cov kab ntau lawm rau cov neeg siv khoom

Tom qab cov kauj ruam zoo tib yam no, ib qho khoom zoo nkauj ntawm cov hniav nyiaj hniav kub tau yug los - txawm tias lub nplhaib, caj dab, lossis ob lub qhwv ntsej, txhua tus embodies precision thiab craftsmanship.

Xaus: Lub Zoo Fusion ntawm Technology thiab Art

Cov hniav nyiaj hniav kub tsob ntoo ciab casting kab tsis yog tsuas yog kev tsim khoom lag luam tab sis kev sib haum xeeb ntawm kev siv tshuab thiab kev kos duab. Los ntawm wax sculpting mus rau hlau casting thiab polishing, txhua kauj ruam yog qhov tseem ceeb. Nws yog qhov kev sib koom ua ke tsis sib haum xeeb uas ua rau txhua daim hniav nyiaj hniav kub ci ci ntsa iab, dhau los ua kev nyiam ua haujlwm ntawm kos duab.

Tom ntej no lub sij hawm koj qhuas ib daim ntawm cov hniav nyiaj hniav kub, nco ntsoov lub "magic saw" tom qab nws-hloov ciab rau hauv hlau, roughness rau hauv radiance. Qhov no yog qhov tseem ceeb ntawm kev tsim cov hniav nyiaj hniav kub niaj hnub.

Koj tuaj yeem tiv tauj peb los ntawm txoj kev hauv qab no:

Whatsapp: 008617898439424

Email:sales@hasungmachinery.com

Lub Vev Xaib: www.hasungmachinery.com www.hasungcasting.com

Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. yog ib lub tuam txhab tsim khoom siv tshuab nyob rau sab qab teb ntawm Suav teb, hauv lub nroog zoo nkauj thiab loj hlob sai tshaj plaws hauv kev lag luam, Shenzhen. Lub tuam txhab yog ib tus thawj coj hauv kev siv tshuab hauv thaj chaw ntawm cov khoom siv cua sov thiab casting rau cov hlau muaj nqis thiab kev lag luam khoom siv tshiab.

Peb txoj kev paub txog kev siv tshuab nqus tsev ua rau peb pab tau cov neeg siv khoom lag luam los ua cov hlau uas muaj cov hlau sib xyaw ua ke ntau, cov hlau platinum-rhodium uas xav tau cov hlau nqus tsev ntau, kub thiab nyiaj, thiab lwm yam.

Xov tooj: +86 17898439424

Email:sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Chaw Nyob: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, Suav Teb 518115