Hasung ƙwararren masani ne kan sarrafa injinan siminti da narke ƙarfe masu daraja tun daga shekarar 2014.

Hasung-Karfe Gas Atomizing Zinare Azurfa Copper 200 Mesh Metal Powder Atomization Machine

Bukatun kasuwanci ne ke tafiyar da mu, muna ci gaba da ingantawa da haɓaka fasahar mu gami da. Wadannan fasahohin suna ba da gudummawa ga tsarin masana'antar mu mai inganci.A cikin filin aikace-aikacen (s) na Metal Casting Machinery.the Precious karfe kayan aiki atomizing Gold Silver Copper foda ƙura ya tabbatar da zama da amfani sosai.

Tare da ƙarfin ƙarfin bincike da haɓaka samfura, Shenzhen Hasung Precious Metals Equipment Co., Ltd yana tabbatar da ƙaddamar da sabbin samfuran akai-akai. Sabon samfurin mu Kayan aikin ƙarfe mai daraja wanda ke daidaita ƙurar ƙurar Zinariya ta Copper sabon salo ne kuma yana da fasali daban-daban. Muna ba mai siye Kayan ƙarfe mai daraja wanda ke sarrafa ƙurar ƙurar Zinariya ta Copper wanda suke buƙata akan farashin da ya dace da aljihunsu. Shenzhen Hasung Precious Metals Equipment Co., Ltd zai samar da ayyuka masu inganci, kuma ya kawo wa abokan ciniki kwarewa mafi kyau. Ta wannan hanyar, kamfanin zai iya ci gaba da ƙarfafa ƙarfinsa na gaba a cikin ƙirƙira fasaha da ƙoƙarin ƙirƙirar cikakkun samfuran Ecological sarkar.

| Wurin Asalin: | Guangdong, China | Yanayi: | Sabo |

| Nau'in Inji: | Injin yin simintin gyare-gyare | Bidiyo mai fita-Duba: | An bayar |

| Rahoton Gwajin Injin: | An bayar | Nau'in Talla: | Sabon samfur 2020 |

| Garanti na ainihin abubuwan haɗin gwiwa: | shekaru 2 | Mahimman Abubuwan Hulɗa: | PLC, Injin, Motoci, Jirgin ruwa, famfo |

| Sunan Alama: | HASUNG | Wutar lantarki: | 380V |

| Ƙarfi: | 15KW-160KW | Girma (L*W*H): | 1180x1070x1925mm |

| Garanti: | shekaru 2 | Mabuɗin Siyarwa: | manyan abubuwan da aka gyara na asali ne daga Japan da Jamus |

| Wurin nuni: | Babu | Masana'antu masu dacewa: | Shagunan Gyaran Injiniya, Shuka Masana'antu, Makamashi & Ma'adinai, Kayan aikin ƙarfe na ƙarfe mai daraja |

| Nauyi (KG): | 2000 | Aikace-aikace: | Platinum Gold, karat zinariya, azurfa da tagulla |

| Gas mai kariya: | Nitrogen ko argon | Sanyaya: | Mai sanyin ruwa ko ruwan famfo |

| Lokacin narkewa: | 15 min | Ƙarfe: | 1KG 2KG 5KG 10KG 100KG 300KG |

| Matsakaicin zafin jiki: | 2200℃ | Hanyar aiki: | Yin aiki mai maɓalli ɗaya don kammala duka tsari |

| tsarin sarrafawa: | Mitsubishi PLC girma | Gishiri: | 80-200 (daidaitacce) |

| Vacuum famfo: | Asalin bututun Vaccum na Jamus -100Kpa |

1 Induction narkewar tanderu iya aiki: 0.2--1kg (karfe)

2 Yanayin aiki: ≤1650 ℃.

3 Samar da wutar lantarki: Mataki na uku, 50Hz 25KW IGBT samar da wutar lantarki

4 Matsin aiki na tsarin bututun ƙarfe yana daidaitawa daga 0 zuwa 6.5MPa

5 Wutar lantarki mai ƙima: (IF fitarwa) 375V

6 Girman zagayawa na ruwa: 50 cubic meters/h (m3/h)

7 Ruwan sanyaya ruwa: 0.2-0.3 MPa (Mpa)

8 Matsakaicin digiri na tsarin Mahimmin digiri na ƙarshe a cikin yanayin sanyi na tanderun fanko bai kai ko daidai da 6 × 10-2pa;

9 Iyakar injin injin aiki: ≤5pa

10 Lokaci don isa matuƙar digiri: ≤30min

11 Matsakaicin haɓakar tsarin: lokacin da tsarin ke cikin ƙimar ƙarancin ƙarancin sanyi, ƙimar hauhawar matsin lamba ya yi ƙasa da ko daidai da 15Pa / h

12 Bukatun fasaha don tundish: ƙarfin yana da kusan 1kg (ƙididdige ta karfe); matsakaicin zafin jiki shine ≤1100 ℃; akwai ayyuka kamar sarrafa lokaci da auna zafin jiki da ƙararrawa.

13 Girman shimfidar kayan aiki: kusan 3m × 2.5m × 3.5m (tsawon × nisa × tsayi)

Bayani

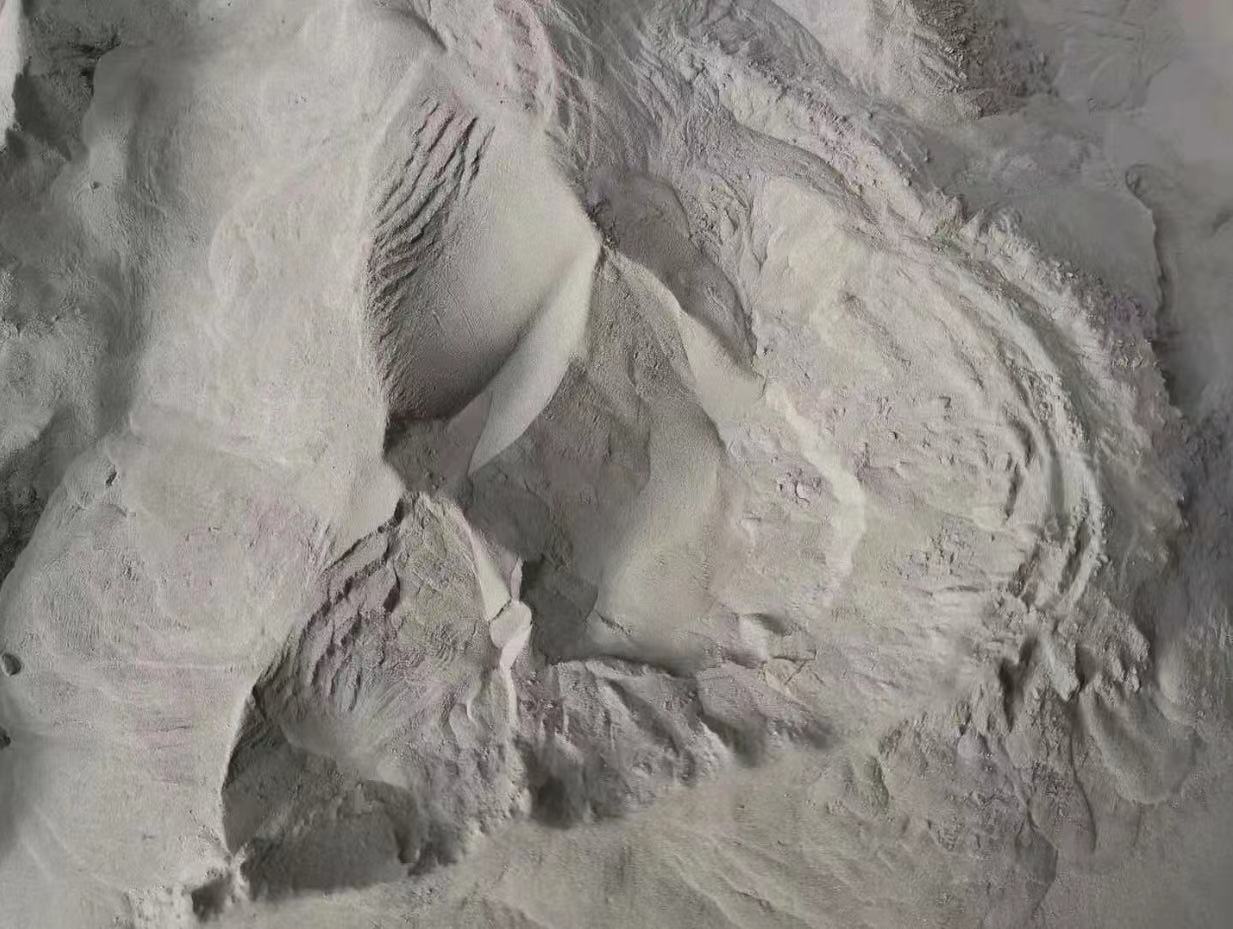

Metal foda atomizing kayan aiki yana halin ƙananan gurɓataccen muhalli, babban matakin foda-siffar foda, ƙananan abun ciki na oxygen da saurin sanyaya da sauransu. Ta hanyar shekaru masu yawa' akai bidi'a da inganta, mu kamfanin ya sabunta mu gas atomization foda-kera dabara da fasaha sau da yawa domin samar da karfe da gami powders na high yi. A halin yanzu, fasahar ta zama babban mahimmanci don tallafawa da inganta kayan aikin samar da foda-atomization, sabon bincike na kayan aiki da sababbin fasahar fasaha.

The aiki ka'idar atomizing kayan aiki yana nufin foda-manufacturer tsari cewa smeling karfe ko gami karkashin wani takamaiman yanayi tare da karfe ruwa zuba obliquely zuwa zafi adana crucible gudãna daga cikin ruwa karkatar da bakin (kasa), da kuma daukan amfani da high matsa lamba gas na bututun ƙarfe don murkushe karfe ruwa a cikin adadi mai yawa na lafiya da karamin ruwa digo; Ruwan da ke tashi ya ƙaƙƙarfa zuwa siffar ball ko ƙananan siffar ƙwallon ƙwallon don haka ya kammala aikin samar da foda.

2. Features da sigogi

I. Metal foda kayan atomizing kayan aiki yana da wadannan fasali:

1.1 Haɗuwa da buƙatun masana'antun ƙarfe da gami da ba za a iya kera su ta hanyar atomization na ruwa ba.

1.2 Samfuran siffar ƙwallon ƙwallon ƙafa ko ƙananan siffar ƙwallon ƙafa.

1.3 Manufacturing yawa musamman gami powders domin shawo kan liquation saboda azumi solidification.

1.4 Yin amfani da hanyar sarrafawa mai dacewa don sa barbashin foda ya isa iyakar da ake buƙata.

The karfe foda atomizing kayan, yafi ƙunshi da wadannan sassa: Medium mita smelting makera (10kg, 25kg, 50kg, 100kg, 200kg), rike tanderu, (10kg, 25kg), atomization tsarin, atomization tank, foda da kuma kura tsarin tattara gas wadata, gas wadata.

tsarin, tsarin sanyaya ruwa, tsarin sarrafawa, matsakaicin matsakaicin wutar lantarki, tsarin samar da wutar lantarki mai riƙe da wutar lantarki (10kg, 25kg matakin wadanda ba a sanye su da tanderu mai riƙewa) da sauransu.

3.1 Induction tanderun narkewa:

Tanderu narkewa mai aiki da yawa a zahiri. Ya ƙunshi jikin tanderu, murfin tanderu, injin ɗagawa, injin auna zafin jiki, naɗaɗɗen shigarwa, injin murɗa murhun wuta. Ƙunƙarar shigar da ita ita ce ginshiƙin narkawa kuma ta dace da matsakaicin ƙarfin; crucible yana cikin induction coil kuma yana iya zubawa da jefawa da wutar lantarki; tsarin karkatarwa (matakin 10kg, 25kg suna sanye take da simintin hannu) an haɗa shi da na'ura mai ba da hanya tsakanin hanyoyin sadarwa kuma ana iya sarrafa saurin simintin ta hanyar bawul ɗin daidaitattun hydraulic.

3.2 Rike tanderu:

Tanderun riƙon kwandon ruwa ne na ƙarfe wanda ke kan tsarin bututun feshi kuma yana da aikin rufewa. Ya fi ƙanƙara fiye da crucible na tsarin narkewa tare da siriri jiki don tabbatar da ƙarfin matsi na ruwa na ƙarfe. Gidan wutar lantarki yana da tsarin dumama da tsarin auna zafin jiki. Tsarin dumama na riƙe tanderu ya kasu kashi biyu na juriya dumama da induction dumama. Juriya dumama iya isa 1200C, yayin da induction dumama a kusa da 1900C. Koyaya, mai amfani dole ne ya zaɓi abin da ya dace. Akwai zaɓuɓɓuka guda biyu na riƙe da wutar lantarki ta makera. Juriya dumama daya mai nauyi mai sarrafa wutar lantarki na yanzu da induction dumama samar da wutar lantarki na matsakaicin mitar SCR daya.

3.3 Tsarin Atomization:

Anyi shi da bututun fesa, bututun iska mai matsa lamba, bawul da sauransu.

3.4 Tanki (ɗakin atomization):

A gaskiya kwantena ne wanda zai iya haɗa dukkan na'urori bisa ga buƙatu. Yana da sarari don ɗigon ruwa na ƙarfe. Bangon ciki shine bakin karfe kuma bangon waje shine carbon karfe kuma girman tanki yana da alaƙa da buƙatun masana'antar foda da iya aiki.

3.5 Tsarin tarin foda da ƙura:

A lokacin aikin samar da foda, akwai musamman foda masu kyau da ke yawo ta cikin bututun tare da saurin iska mai saurin gaske. Yana da aikin tarawa na biyu lokacin da ke cikin kayan aiki kuma yana samun sakamako na rage gurɓataccen muhalli da amfani da kayan. A halin yanzu ana sarrafa tarin ta hanyar na'urar raba guguwa da kuma tattara lokacin ruwa.

3.6 Tsarin Ruwa:

Tsarin ya fi ba da wutar lantarki mai ƙarfi zuwa karkatar da na'urar da haɓaka murfin tanderu.

3.7 Tsarin samar da iskar gas:

Ya ƙunshi bawul mai hankali, bawul ɗin sarrafa matsa lamba, bawul mai rage matsa lamba, firikwensin matsa lamba, babban tiyo mai matsa lamba da

alamar matsa lamba. Yin amfani da tsarin mai hankali, ma'aikatan aiki na iya daidaita matsi na iskar gas na atomization bututun ƙarfe a kan layi a kowane lokaci yayin aiki mai nisa da yin rikodin tare da PC don tunani da bincike daga baya don samun madaidaicin fasahar sarrafa foda. Hakanan tsarin na iya zama na zaɓi, ya kasu zuwa sarrafa hannu da sarrafawa ta atomatik.

Tare da fiye da haƙƙin mallaka da takaddun shaida 30

Tambaya: Yaya tsawon lokacin garantin injin ku?

A: Garanti na shekaru biyu.

Tambaya: Yaya ingancin injin ku?

A: Tabbas ita ce mafi inganci a kasar Sin a wannan masana'antar. Duk injuna suna amfani da mafi kyawun shahararrun samfuran sunaye na duniya. Tare da babban aiki da ingantaccen matakin inganci.

Tambaya: Ina masana'anta take?

A: Muna cikin Shenzhen, China.

Tambaya: Menene zamu iya yi idan muna da matsala tare da injin ku yayin amfani?

A: Na farko, induction ɗinmu na dumama da injunan simintin gyare-gyare suna da inganci mafi inganci a cikin wannan masana'antar a China, abokan ciniki

yawanci zai iya amfani da shi fiye da shekaru 6 ba tare da wata matsala ba idan yana ƙarƙashin yanayin al'ada ta amfani da kulawa. Idan kuna da wata matsala, muna buƙatar ku samar mana da bidiyo don bayyana menene matsalar don injiniyanmu ya yi hukunci ya gano muku mafita. A cikin lokacin garanti, za mu aiko muku da sassan kyauta don sauyawa. Bayan lokacin garanti, za mu samar muku da sassan a farashi mai araha. Ana ba da tallafin fasaha na tsawon rayuwa kyauta.

Lambar waya: +86 17898439424

Imel: sales@hasungmachinery.comda

WhatsApp: 0086 17898439424

Adireshi: No.11, Titin 1st Jinyuan, Al'ummar Heao, Titin Yuanshan, Gundumar Longgang, ShenZhen, China 518115