Hasung - Precious metal Gas Atomizing Gold Silver Copper 200 Mesh Metal Powder Atomization Machine

Driven by business needs, we have been constantly optimizing and upgrading our technologies including. These technologies contribute to our high-efficiency manufacturing process.In the application field(s) of Metal Casting Machinery.the Precious metal equipment atomizing Gold Silver Copper powder dust proves to be very useful.

With strong ability of product research and development, Shenzhen Hasung Precious Metals Equipment Co., Ltd ensures new products are launched on a regular basis. Our new product Precious metal equipment atomizing Gold Silver Copper powder dust is a totally new series and has different features. We offer buyer Precious metal equipment atomizing Gold Silver Copper powder dust that they need at prices that fit their pocket. Shenzhen Hasung Precious Metals Equipment Co., Ltd will provide high-quality services, and bring customers a better experience. In this way, the company can continue to strengthen its future strength in technological innovation and strive to create complete products Ecological chain.

| Place of Origin: | Guangdong, China | Condition: | New |

| Machine Type: | Casting machine | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | New Product 2020 |

| Warranty of core components: | 2 years | Core Components: | PLC, Engine, Motor, Pressure vessel, Pump |

| Brand Name: | HASUNG | Voltage: | 380V |

| Power: | 15KW-160KW | Dimension(L*W*H): | 1180x1070x1925mm |

| Warranty: | 2 years | Key Selling Points: | main components are original from japan and germany |

| Showroom Location: | None | Applicable Industries: | Machinery Repair Shops, Manufacturing Plant, Energy & Mining, Precious metal atomizing powder making equipment |

| Weight (KG): | 2000 | Application: | Platinum Gold, karat gold,silver and copper |

| Protective gas: | Nitrogen or Argon | Cooling: | Water chiller or tap water |

| Melting time: | 15 mins | Metal capacity: | 1KG 2KG 5KG 10KG 100KG 300KG |

| Max temperature: | 2200℃ | Operation method: | One-key operation to complete the entire process |

| control system: | Mitsubishi PLC | Grit: | 80-200 (adjustable) |

| Vacuum pump: | Original German Vaccum pump -100Kpa |

1 Induction melting furnace capacity: 0.2--1kg (steel)

2 Working temperature: ≤1650℃.

3 Power supply: Three-phase, 50Hz 25KW IGBT power supply

4 The working pressure of the atomizing nozzle system is adjustable from 0 to 6.5MPa

5 Rated output voltage: (IF output) 375V

6 Cooling water circulation volume: 50 cubic meters/hour (m3/h)

7 Cooling water pressure: 0.2-0.3 MPa (Mpa)

8 The vacuum degree of the system The ultimate vacuum degree in the cold state of the empty furnace is less than or equal to 6×10-2pa;

9 Working vacuum limit: ≤5pa

10 Time to reach ultimate vacuum degree: ≤30min

11 System pressure rise rate: when the system is in the cold limit vacuum degree, the pressure rise rate is less than or equal to 15Pa/h

12 Technical requirements for the tundish: the capacity is about 1kg (calculated by steel); the maximum temperature is ≤1100℃; there are functions such as time control and temperature measurement and alarm.

13 Equipment layout size: about 3m×2.5m×3.5m (length×width×height)

Description

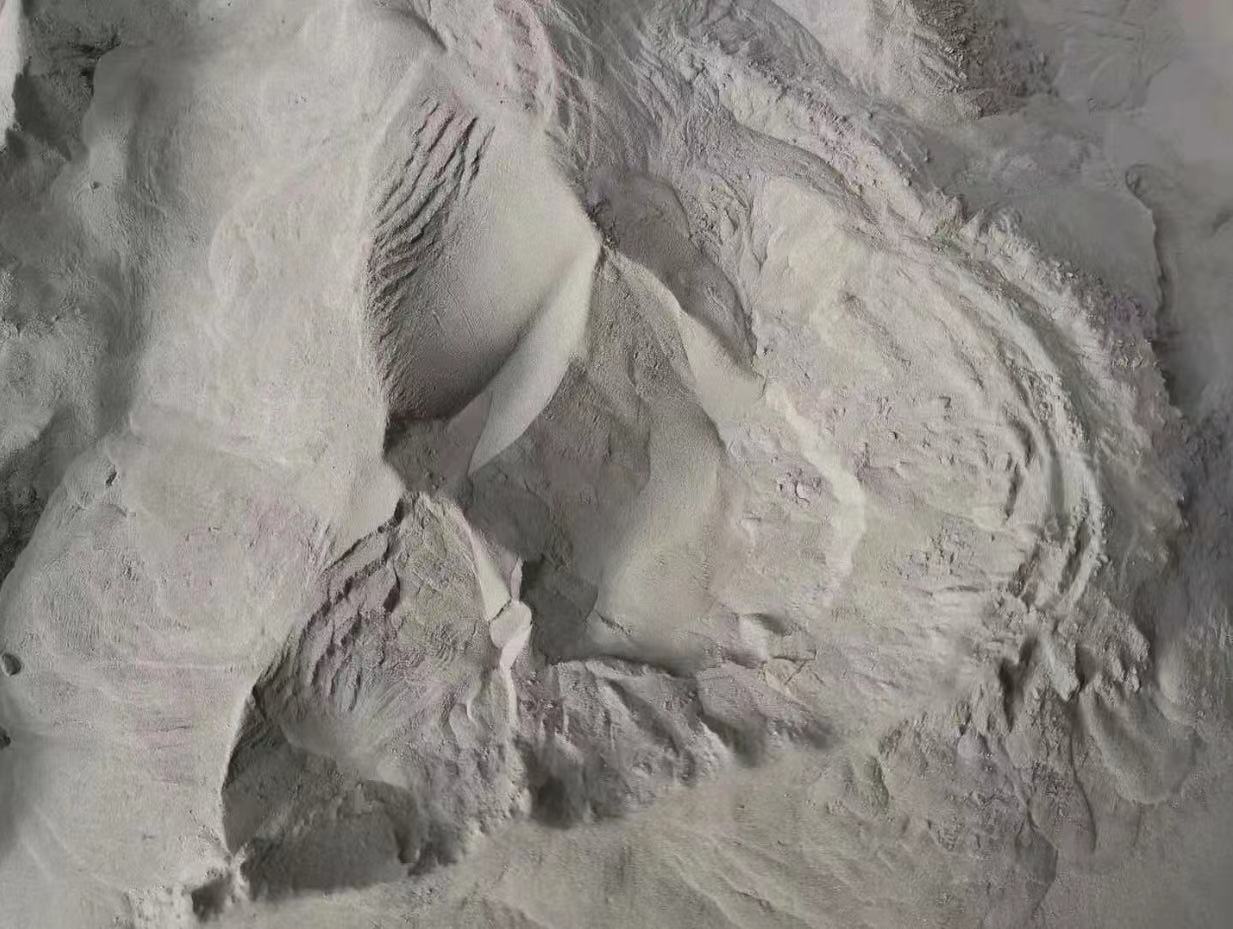

Metal powder atomizing equipment is characterized by small environmental pollution, high degree of ball-shape powder, low oxygen content and fast cooling rate and so on. Through many years’ constant innovation and improvement, our company has updated our gas atomization powder-manufacturing technique and technology several times in order to produce metal and alloy powders of high performance. Currently, the technology has become the leading factor to support and promote atomization powder-manufacturing equipment, new material research and new technology development.

The operating principle of atomizing equipment refers to the powder-manufacturing process that smelting metal or alloy under certained condition with metal liquid poured obliquely to heat preservation crucible flowing out through liquid diversion mouth (downward), and takes advantage of the high pressure gases of nozzle to crush metal liquid into large amounts of fine and small liquid drop; The flying liquid drops solidify into ball-shape or sub ball-shape particles and thus complete the whole powder-manufacturing process.

2. Features and parameters

I. Metal powder atomizing equipment has the following features:

1.1 Meeting the requirements of manufacturing metals and its alloy that can not manufactured by water atomization.

1.2 Manufacturing ball-shape or sub ball-shape powder.

1.3 Manufacturing numerous special alloy powders for overcoming aliquation due to fast solidification.

1.4 Adopting suitable processing method to make the powder’s particle reach the required range.

The metal powder atomizing equipment mainly contains the following parts: Medium frequency smelting furnace(10kg, 25kg, 50kg, 100kg, 200kg), holding furnace, (10kg, 25kg), atomization system, atomization tank, powder and dust collecting system, gas supply

system, water cooling system, control system, medium frequency power source, holding furnace power supply system(10kg, 25kg level ones are not equipped with holding furnace) and so on.

3.1 Induction smelting furnace:

It is a multi-function induction smelting furnace in fact. It is composed of furnace body, furnace cover, elevation mechanism, temperature measuring mechanism, induction coil, tilting furnace mechanism. The induction coil is the core of the smelting and matches the intermediate power; the crucible is located in the induction coil and it can pour and cast with electricity; the tilting mechanism(10kg, 25kg level ones are equipped with manual casting) is connected with hydraulic and the casting speed can be controlled by the hydraulic proportional valve.

3.2 Holding furnace:

The holding furnace is a metal liquid container located on the spray nozzle system and has the insulation function. It is smaller than the crucible of smelting system with slender body to ensure the metal liquid’s pressure energy. The holding furnace has heating system and temperature measuring system. The heating system of holding furnace is divided into two types of resistance heating and induction heating. The resistance heating can reach 1200C, while the induction heating around 1900C. However, user have to choose the suitable crucible material. There are two choices of holding furnace’s power supply. The resistance heating one is heavy current power regulator and the induction heating one SCR medium frequency power supply.

3.3 Atomization system:

It is made of spray nozzle, high pressure windpipe, valve and so on.

3.4 Tank(Atomization chamber):

Actually it is a container that could connect all the devices according to the requirements. It is space for condensation of metal liquid drops. The internal wall is stainless steel and the external wall is carbon steel and the size of the tank is related to the powder manufacturing requirements and capcity.

3.5 Powder and dust collection system:

During the powder-manufacturing process, there are especially fine powders flying through the pipeline along the high speed air current. It has the secondary collection function when going through the equipment and achieves the effect of reduced environmental pollution and consumption of materials. At present the colleting is processed through cyclone separating device and water phase collection.

3.6 Hydraulic system:

The system mainly provice hydraulic power to the tilting of the device and elevation of the furnace cover.

3.7 Gas supply system:

It consists of intelligent valve, pressure control valve, pressure-reducing valve, pressure sensor, high pressure hose and

pressure indicator. Adopting the intelligent system, the operating personnel can adjust the gas supply pressure of atomization nozzle online at any time during long distance operation and record with PC for later reference and research in order to acquire the precise powder-manufacturing operation technique. The system can also be optional, divided into manual control and automatic control.

With more than 30 patents and certificates

Q: How long does your machine warranty last?

A: Two years warranty.

Q: How is your machine quality?

A: Definitely it's the highest quality in China in this industry. All machines apply the best world famous brands name parts. With great workmanship and reliable highest level quality.

Q: Where are your factory located?

A: We are located in Shenzhen, China.

Q: What can we do if we have problems with your machine while using?

A: First, our induction heating machines and casting machines are with highest quality in this industry in China, customers

usually could use it for more than 6 years without any problems if it's under normal condition using and maintenance. If you have any troubles, we'll need you to provide us a video to describe what the problem is so that our engineer will judge and find out the solution for you. Within warranty period, we'll send you the parts free of charge for replacement. After warranty time, we'll provide you the parts at an affordable costs. Long lifetime technical support is offered freely.

Tel: +86 17898439424

E-mail: sales@hasungmachinery.com

WhatsApp: 0086 17898439424

Address: No.11, Jinyuan 1st Road, Heao Community, Yuanshan Street, Longgang District, ShenZhen, China 518115